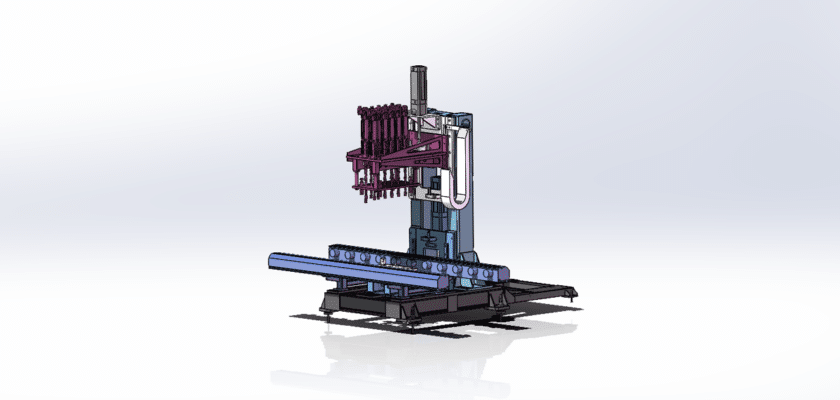

The 12-Head Automatic Screw Machine drawing provides a comprehensive schematic of a high-capacity automated assembly system designed for the efficient insertion and tightening of screws across multiple stations. This machine is ideal for high-volume production environments, particularly in industries such as automotive, electronics, and furniture manufacturing.

Key Features:

- Machine Layout: The drawing illustrates the overall configuration of the 12-head automatic screw machine, showcasing its dimensions, layout, and the arrangement of the twelve screw insertion heads. The design is optimized for efficient use of space while maximizing productivity.

- Multi-Head Operation: Detailed information on the twelve operational heads is provided, each capable of inserting and tightening screws simultaneously. This multi-head setup significantly increases throughput, allowing for faster assembly processes.

- Screw Insertion Mechanism: The drawing highlights the advanced screw insertion mechanism, detailing how screws are fed into each head using vibratory bowls or feeders. Specifications regarding screw sizes, types, and feeding rates are included to ensure compatibility with various applications.

- Tightening Mechanism: Information on the tightening process is provided, showcasing the use of electric or pneumatic torque tools that ensure precise torque application to each screw. This section includes specifications on torque settings and control features to maintain consistent quality.

- Control Systems: The drawing includes details on the control mechanisms used to operate the machine, such as user-friendly interfaces for programming operational parameters, monitoring performance, and integrating with other production equipment.

- Safety Features: Essential safety components, such as emergency stop buttons, safety enclosures, and sensors for detecting jams or misalignments, are clearly marked to enhance operator safety and comply with industry standards.

- Support Structure: The robust frame and support components are depicted, emphasizing stability and durability to withstand the operational stresses of high-speed screw insertion. Structural assessments ensure safe operation under various load conditions.

- Maintenance Accessibility: The design includes considerations for easy access to critical components for routine maintenance and inspections, promoting efficient upkeep and minimizing downtime.

This drawing serves as a vital resource for engineers, production managers, and maintenance personnel, providing comprehensive insights into the design, implementation, and operation of 12-head automatic screw machines in diverse manufacturing applications, ensuring efficiency and quality in high-volume assembly processes.