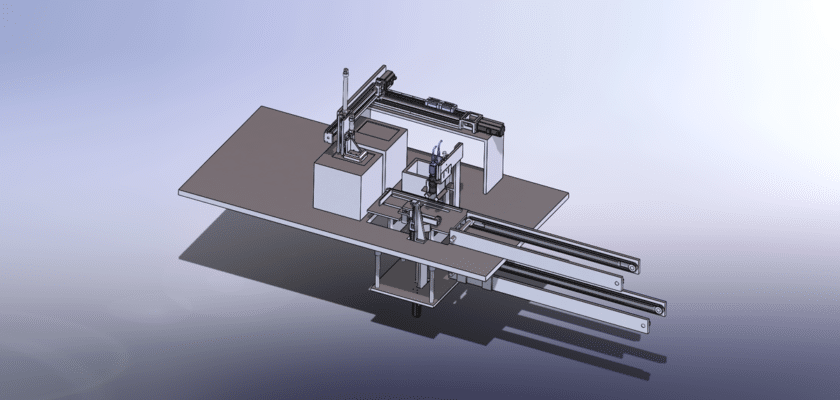

The 12-Piece Battery Stacking system is an innovative solution designed to efficiently organize and stack battery units in industrial environments. This machine is ideal for manufacturing and logistics facilities where large volumes of battery handling and stacking are required. By automating the stacking process, it improves both speed and safety, while reducing manual labor.

Main Features:

- High Capacity: The system is designed to stack up to 12 pieces of batteries simultaneously, making it ideal for high-volume battery production lines or warehouses.

- Enhanced Efficiency: Automating the stacking process minimizes human error and increases throughput, allowing operators to focus on other critical tasks while the machine handles the stacking operation.

- Sturdy and Durable: Built with high-quality materials, the 12-Piece Battery Stacking system is designed to withstand heavy-duty operations, ensuring long-term reliability and reduced maintenance costs.

- User-Friendly Operation: With an intuitive control interface, the system is easy to operate, minimizing training time and ensuring that operators can quickly adjust settings to optimize performance.

- Safety Features: Equipped with safety mechanisms to ensure the safe handling of batteries, reducing the risk of accidents in high-speed production environments.

Download the drawing for the 12-Piece Battery Stacking system to access detailed technical specifications and explore how this solution can benefit your operations.