The 2.5-Ton L-Type Welding Positioner is a versatile and essential piece of equipment for any advanced fabrication facility looking to optimize the welding of complex, asymmetrical workpieces. Unlike traditional tilt-and-turn tables, the L-type configuration provides a unique offset axis that allows for a much larger swing diameter. This design is particularly advantageous for workpieces with significant projections or those that require deep access into the internal structure, as the “L” arm moves the rotation center away from the main column, preventing interference during 360-degree cycles.

By downloading this technical drawing, you are accessing a professional-grade blueprint designed for high-load stability. The 2.5-ton capacity ensures that the machine can handle substantial industrial components, such as large valve bodies, motor housings, and custom structural frames. The geometry provided in these files focuses on maintaining a low center of gravity even when the workpiece is tilted, which is critical for operator safety and the precision of automated welding torches.

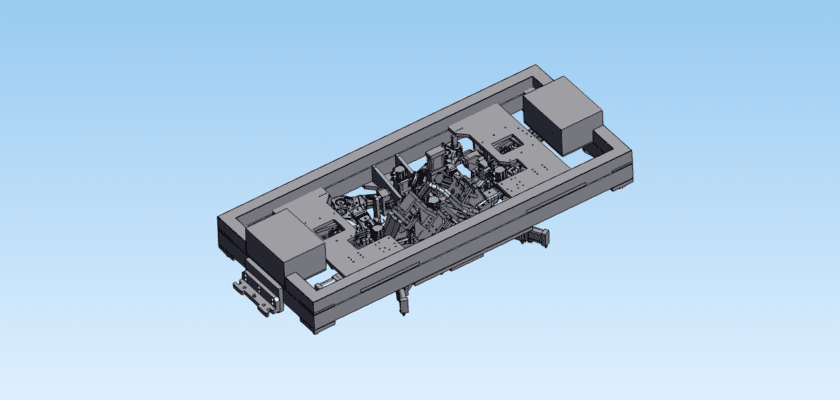

Our CAD drawing provides a comprehensive view of the mechanical assembly, including the heavy-duty slewing bearings and the reinforced vertical support column. For engineers and shop managers, this documentation is a vital resource for plant layout planning and ensuring that your welding cell can accommodate the specific reach and clearance requirements of your most challenging projects. Download this drawing today to streamline your manufacturing process and elevate your shop’s technical capabilities.

Key Features:

- High Swing Clearance: The L-shaped arm design allows for the rotation of large, bulky items that would otherwise collide with the base of a standard positioner.

- 2.5-Ton Load Rating: Engineered with a high safety factor to support and manipulate industrial loads up to 2,500 kg with ease.

- Precision Gear Drive: Utilizes advanced motor and gearbox specifications to ensure smooth, jitter-free rotation for high-quality weld beads.

- Variable Speed Control: Designed for integration with control systems that allow for precise RPM adjustments to match various welding processes.

- Stable Footprint: Features a heavy-duty base plate design that ensures maximum rigidity and minimizes vibration during high-capacity operations.