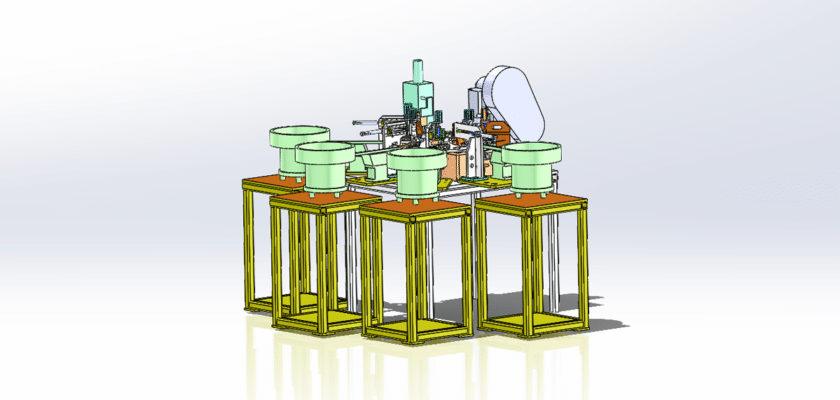

This detailed drawing of the 3M Copper Head Assembly Machine showcases a specialized system designed for the efficient assembly of copper head components in various electronic applications. Engineered to optimize production workflows and ensure high-quality connections, this machine is ideal for manufacturers in the electronics and telecommunications industries.

Key Features of the Drawing:

- Automated Assembly Process: The machine employs advanced automation technology, significantly reducing manual intervention and enhancing production efficiency during the assembly of copper head components.

- Precision Alignment and Placement: Equipped with high-precision alignment systems, it ensures accurate positioning of copper heads, which is critical for maintaining electrical integrity and performance.

- User-Friendly Control Interface: The intuitive control panel allows operators to easily program and adjust settings, facilitating quick changes for different component specifications and production requirements.

- Robust and Durable Construction: Built with high-quality materials, the machine is designed for reliability and longevity, ensuring consistent performance in high-demand industrial environments.

- Versatile Compatibility: Suitable for various copper head configurations and sizes, making it adaptable for diverse applications in electronic assembly.

- Integrated Quality Control: Features real-time monitoring systems to ensure the quality of the assembly process, helping to minimize defects and maintain high standards.

This drawing serves as a vital resource for engineers and manufacturers looking to implement effective and efficient assembly solutions for copper head components in their production lines.