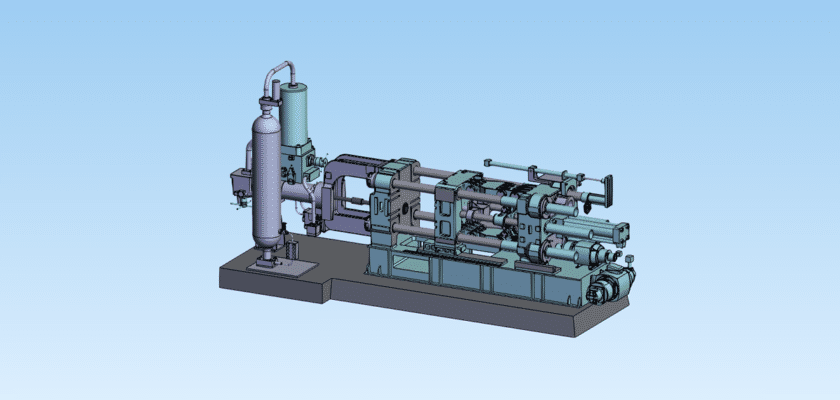

Get instant access to the awesome technical drawing package for a 500-Ton Die Casting Machine! MechStream is offering these professional blueprints for download now. This machine is an essential resource for high-volume metal component manufacturers, particularly those specializing in aluminum, zinc, or magnesium alloys. The 500-ton clamping force rating signifies a powerful machine capable of producing complex, medium-to-large castings with excellent surface finish and dimensional accuracy.

Our comprehensive package grants fast access to the ultimate design specifications of this incredible production equipment. The drawing set includes detailed plans for the massive, high-rigidity frame (platen and tie bars), the powerful hydraulic clamping system, the injection unit mechanism, and the automated component ejection system. Understanding the stress distribution in the platens and the precision control of the injection speed is key to maximizing casting quality and machine lifespan. By downloading these powerful technical files, you gain all the necessary dimensional data, structural specifications, and assembly layouts for accurate fabrication, maintenance, or rigorous engineering analysis. Stop compromising on production quality. Download the complete 500-Ton Die Casting Machine drawing today and leverage professional-grade schematics to ensure your machine meets the highest standards of reliability and high-tonnage performance. This resource is indispensable for casting and heavy machinery engineers.

Key Features:

- High-Tonnage Clamping System: Detailed schematics of the large hydraulic cylinder and toggle linkage designed to generate 500 tons of clamping force.

- Platen and Tie Bar Specification: Structural drawings specifying the massive dimensions and material requirements for the fixed and moving platens and the tie bars.

- Injection Unit Mechanism: Plans for the piston/plunger assembly and the chamber interface required for injecting molten metal at high speed and pressure.

- Ejection System Layout: Schematics detailing the integrated hydraulic or mechanical system used for automatically pushing the finished casting out of the mold.

- Die Interface Standardization: Dimensions and bolt patterns for mounting the large, custom casting dies onto the platens.