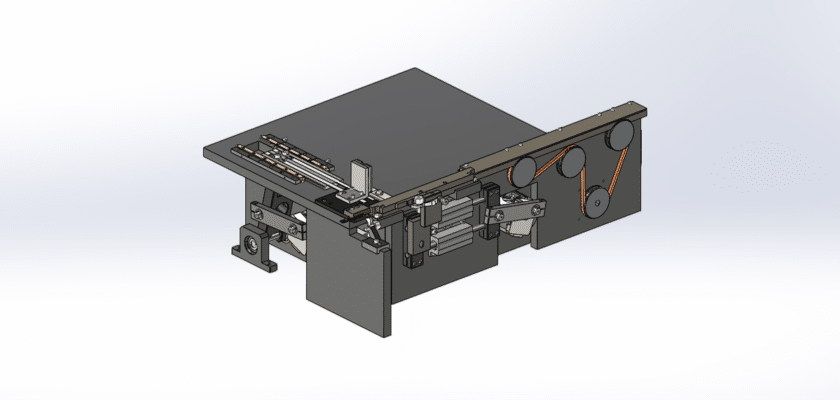

The Pin Connector Processing Equipment is a highly advanced machine designed for the efficient manufacturing and assembly of pin connectors. This equipment is essential in industries like automotive, electronics, and telecommunications, where precision and reliability are paramount. The machine is engineered to handle various types of pin connectors, ensuring high-quality output and precision in every step of the processing.

One of the key features of this equipment is its high-speed processing capability. It allows for mass production without compromising on accuracy, making it ideal for companies with large production volumes. The automated feeding system ensures smooth operation and minimizes the need for manual intervention, reducing the risk of human error and enhancing overall productivity.

The customizable settings of the equipment allow for easy adjustments based on the specific type of pin connector being processed. Whether it’s crimping, insertion, or testing, the machine can be tailored to meet the demands of different projects. This flexibility makes it suitable for a wide range of applications, from small-scale batches to large-scale industrial production.

In addition, the integrated quality control features ensure that only connectors meeting stringent standards are produced. The system detects defects or irregularities in real-time, allowing for immediate corrective actions. This guarantees consistent product quality and ensures compliance with international standards.

In summary, the Pin Connector Processing Equipment offers a reliable and efficient solution for manufacturers looking to streamline their production processes while maintaining high standards of quality and precision.