A robot grabbing mechanism, also known as a robotic gripper or end effector, is the device attached to the end of a robotic arm that allows it to interact with its environment. It is the robot’s “hand,” designed to perform tasks such as picking up, holding, and placing objects. These mechanisms come in a wide variety of forms, from simple two-fingered parallel grippers to complex vacuum systems and magnetic tools, each tailored for a specific application. The choice of gripper is crucial for the success of any automated task, as it must be able to securely grasp the object without damaging it, while also providing the necessary speed and precision for the job.

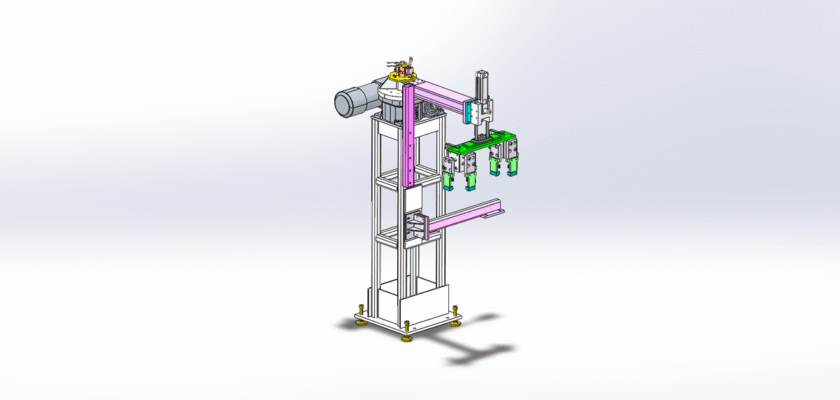

This free downloadable drawing provides a detailed look at the design and function of a common robotic grabbing mechanism. It’s a fantastic resource for mechanical engineers, robotics students, and automation enthusiasts who want to understand the principles behind robotic manipulation.

Key Features:

- Versatile Gripper Jaws: The drawing highlights the interchangeable and adjustable jaws that allow the gripper to handle a wide range of object shapes and sizes.

- Actuation System: The plans illustrate the pneumatic or servo-driven system that provides the force and control needed to open and close the gripper with precision.

- Integrated Sensors: The design showcases the use of force and proximity sensors that provide feedback to the robot, enabling it to adjust its grip and prevent damage to delicate parts.

- Quick-Change Interface: The drawing details the modular interface that allows the gripper to be quickly swapped out for different tools, maximizing the robot’s versatility on a production line.