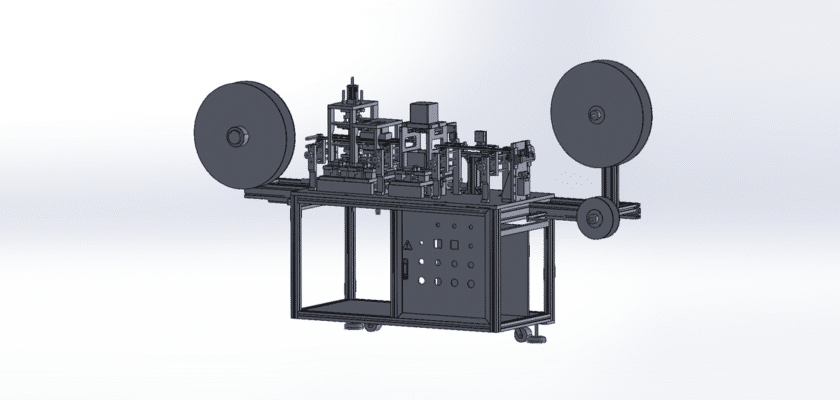

Delve into the core of modern electronics packaging with this free technical drawing of a Carrier Tape Forming Machine. This invaluable resource is perfect for engineers, students, and manufacturers who need to understand the mechanics behind creating the ubiquitous embossed carrier tapes used for housing and transporting electronic components. The drawing details a thermoforming-based system, which is the industry standard for creating precision pockets for sensitive surface-mount devices (SMDs).

The schematic illustrates the key stages of the forming process: material feeding, heating, pocket forming, and slitting. By studying this drawing, you’ll gain insight into how a flat plastic film is heated to a pliable state and then precisely pressed by a series of dies to create the pockets that hold tiny components like ICs, resistors, and capacitors. The design also shows the intricate details of the transport mechanism, which ensures accurate pitch and pocket consistency—a critical factor for automated pick-and-place machines in the assembly process. Download this drawing to master the principles of high-volume, high-precision carrier tape production.

Key Features:

- Thermoforming Process: The drawing provides a detailed look at the heating and molding sections, showing how plastic film is shaped into pockets with high dimensional accuracy.

- Precision Pitch Control: The design highlights the importance of a synchronized feeding mechanism to ensure the pockets are consistently spaced according to industry standards (EIA-481).

- Modular Tooling: The plans show a system designed to accommodate different pocket sizes and tape widths, allowing for flexible production runs with minimal downtime.

- Integrated Slitting: The drawing details the final stage where the formed tape is trimmed to the correct width and wound onto reels, showcasing a seamless end-to-end process.

- Material Handling: Gain an understanding of the automated systems for feeding raw material and collecting the finished carrier tape, which are essential for continuous operation.