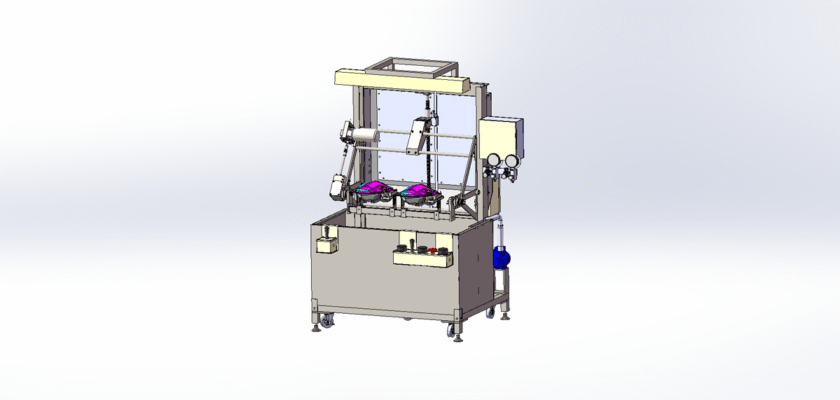

Explore the core of modern manufacturing with our free technical drawings of a Mold Forming Machine. This detailed blueprint set is an essential resource for anyone involved in plastic injection molding, from engineering students and professional designers to seasoned manufacturers. The drawings provide a comprehensive look at the intricate mechanisms that are the backbone of high-volume production of plastic parts. You’ll gain insight into how raw materials are heated, injected under high pressure into a mold cavity, and then ejected as a finished product, all with remarkable speed and precision.

Our high-quality, CAD-compatible drawings are available for instant download at no cost. By studying these plans, you will understand the critical components of a mold forming machine, including the clamping unit that holds the mold securely, the injection unit that delivers the molten plastic, and the control systems that regulate the entire process. This resource is perfect for learning about the principles of thermoplastic molding, troubleshooting existing equipment, or designing your own custom parts. Download this valuable tool today and unlock a deeper understanding of one of the most important processes in the manufacturing industry.

Key Features:

- Clamping Unit Details: The drawings showcase the robust clamping system, detailing the platen, tie bars, and hydraulic or toggle mechanisms that apply immense force to hold the mold shut.

- Injection System Schematics: Blueprints illustrate the barrel, screw, and nozzle design, showing how plastic pellets are melted and injected into the mold with precision.

- Complex Ejection Mechanisms: The plans provide a clear view of the system that automatically ejects the finished part, ensuring rapid cycle times and continuous operation.

- Core Design Principles: A perfect educational tool for understanding the physics of material flow and the mechanical design of a high-speed production machine.