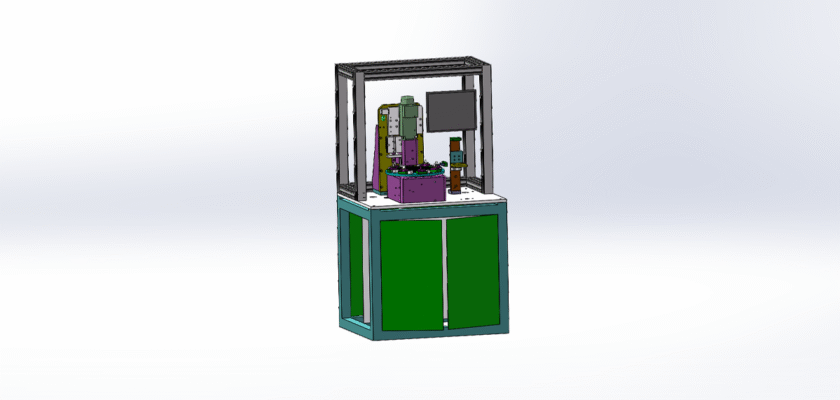

Step into the world of electronics manufacturing with our detailed drawing of a USB Case Punching Machine. This free, downloadable resource is a crucial tool for engineers, designers, and students interested in high-speed production and precision automation. The machine is specifically designed to punch the necessary port openings and ventilation holes into plastic or metal USB cases, a critical step in the assembly of flash drives, external hard drives, and other electronic accessories. Our drawing provides an in-depth look at the machine’s core components, including the robust punching press, the automated case feeding system, and the precision die sets. Understanding the mechanics of this machine is essential for anyone involved in electronics casing manufacturing, as it showcases how high-volume production is achieved with consistent quality and minimal waste. This document is an excellent educational tool for grasping the principles of mechanical stamping and is a valuable asset for any professional or academic library.

Key Features:

- Automated Feeding System: The design includes a hopper and a conveyor or vibratory feeder that automatically supplies USB cases to the punching station, ensuring a continuous and high-speed operation.

- High-Precision Punching: The drawing details the robust punching press and the precision-machined die sets that create clean, burr-free openings in the USB cases, crucial for a professional finish.

- Die Versatility: The machine is designed with a quick-change die system, allowing for rapid adaptation to different USB case designs and port configurations with minimal downtime.

- Safety Mechanisms: The blueprint illustrates key safety features such as protective guards and an emergency stop button, ensuring a secure working environment for operators.

- Compact and Efficient: The machine’s design is optimized for a small footprint, making it ideal for integrating into existing assembly lines where space is a premium.