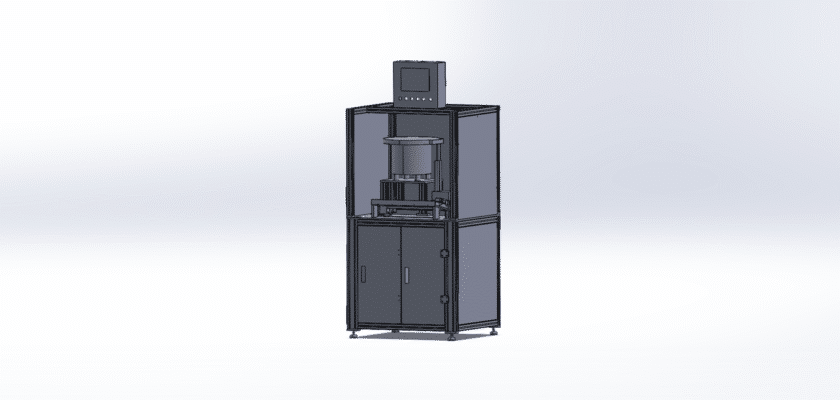

Step into the world of industrial automation with our detailed drawing of an Automatic Rubber Ring Ferrule Machine, available for a free download. This essential technical document is an indispensable resource for students, engineers, and manufacturing professionals keen to understand the inner workings of automated assembly lines. Automatic ferrule machines are widely used in a variety of industries, including plumbing, automotive, and electronics, where they are used to securely install ferrules and rubber rings onto cables, hoses, or other components. The machine’s ability to perform this repetitive task with high precision and speed significantly boosts production efficiency and ensures consistent product quality, while also reducing the potential for human error.

This comprehensive CAD drawing provides an in-depth look at the complex mechanical and control systems that make this machine so effective. It illustrates how components are automatically fed from a hopper, sorted, oriented, and then precisely placed and secured. The design highlights the synergy between the pneumatic and electrical systems, showcasing how a PLC (Programmable Logic Controller) orchestrates the entire process. This free download is a great tool for academic study, a reference for custom machine design, or simply to satisfy your curiosity about how these sophisticated automation solutions function in a real-world setting.

Key Features:

- Vibratory Bowl Feeder: The design features a high-speed vibratory bowl feeder that automatically sorts and feeds rubber rings or ferrules, ensuring a continuous supply to the assembly station.

- Pneumatic Actuation System: The drawing details a reliable pneumatic system that controls the precise movements of the grippers and placement tools, guaranteeing accurate positioning and gentle handling of components.

- Microprocessor Control: The machine is managed by an integrated microprocessor or PLC, allowing for programmable control over the entire assembly cycle, from feeding to final crimping or fitting.

- Modular Design: The blueprint illustrates a modular construction that allows for easy maintenance, rapid tool changes for different component sizes, and seamless integration into larger production lines.