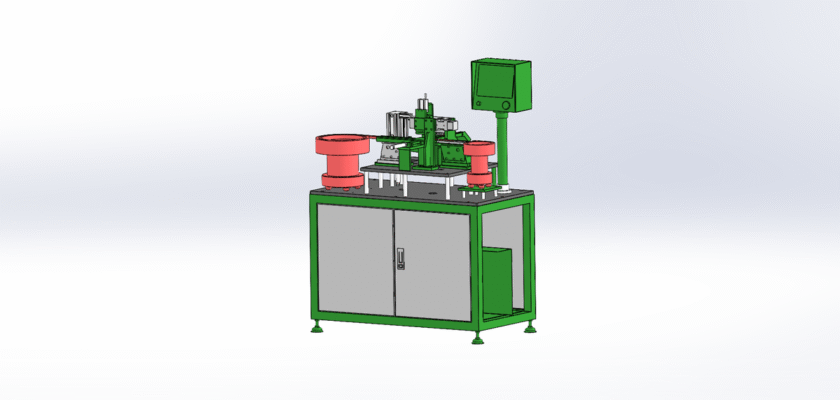

A slider switch terminal bending machine is a specialized piece of equipment designed to accurately and rapidly bend the metal terminals of slider switches. This automated process is critical in the electronics manufacturing industry, where high-volume production requires precise and consistent bending to ensure the switches can be correctly mounted onto a circuit board. Manual bending is not only slow but can also damage the delicate internal components of the switch. This machine eliminates these issues, guaranteeing a perfect bend every time and significantly increasing production efficiency. This comprehensive drawing, available for free download, provides a detailed blueprint of a professional-grade terminal bending machine. It is an invaluable resource for mechanical engineers, electronics manufacturers, and students in automation who want to understand the intricate mechanical and pneumatic systems that enable such precise and repeatable action.

Key Features:

- High-Precision Bending Die: The drawing details a custom bending die that ensures a consistent angle and perfect shape for every terminal, crucial for automated circuit board assembly.

- Automated Feeding System: The blueprints showcase a parts feeder and a delivery system that precisely presents each switch to the bending station, ensuring a continuous and uninterrupted workflow.

- Robust and Reliable Design: The machine is engineered for continuous industrial use, with a strong frame and durable components built to withstand high-speed, repetitive cycles with minimal maintenance.

- Pneumatic Actuation: The drawing highlights the use of a pneumatic cylinder for fast and powerful bending action, while allowing for adjustable force to accommodate different switch types.