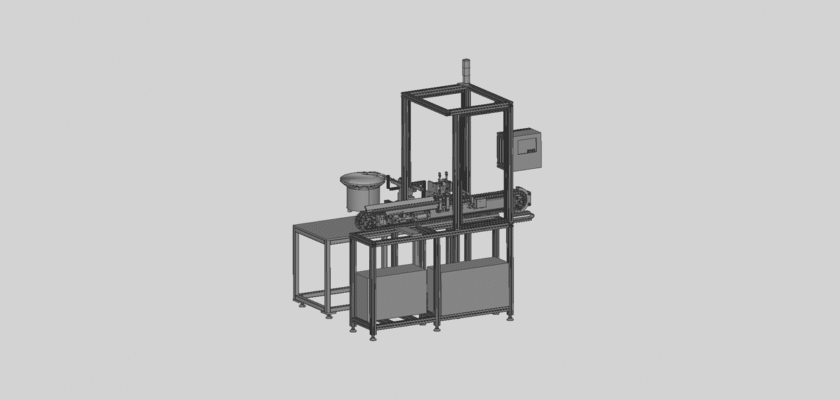

A spark plug paper sleeve packaging machine is a specialized automated system designed to swiftly and securely package spark plugs into protective paper or cardboard sleeves. This crucial piece of equipment is essential for the automotive parts industry, as it ensures that delicate spark plugs are protected from damage during handling, shipping, and storage. By automating this process, manufacturers can achieve high-speed production, guarantee a consistent, professional appearance for every package, and significantly reduce labor costs. This comprehensive drawing, available for free download, provides a detailed blueprint of a professional-grade packaging machine. It is an invaluable resource for mechanical engineers, manufacturing specialists, and students in automation who want to understand the intricate mechanical and pneumatic systems that make this equipment so efficient. The plans illustrate how the machine feeds spark plugs, forms the paper sleeve around them, and seals the package with precision and speed.

Key Features:

- High-Speed Automation: The design is engineered for rapid and continuous operation, capable of packaging hundreds of spark plugs per minute to meet high-volume production demands.

- Precision Handling System: The blueprints showcase a gentle yet precise handling mechanism that safely guides the spark plugs through the machine, preventing damage to the electrodes or insulators.

- Integrated Sleeve Forming: The machine features a clever paper-feeding and forming unit that creates a custom sleeve from a flat blank or roll, minimizing material waste and ensuring a perfect fit.

- Compact and Efficient Design: The drawing highlights an optimized layout that fits a powerful packaging system into a small footprint, making it ideal for integration into existing production lines.