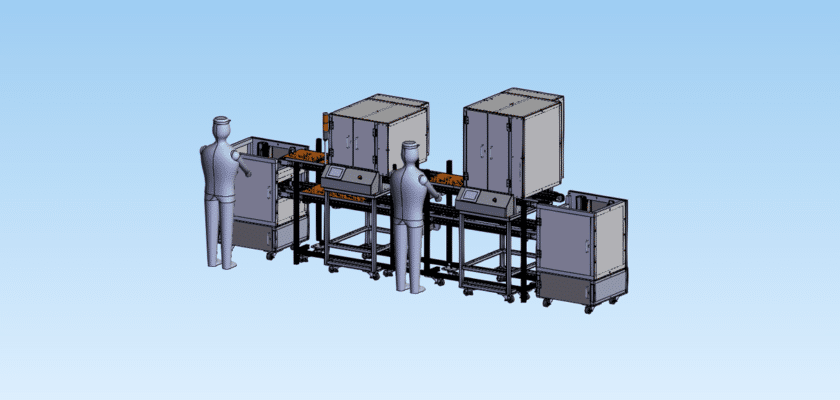

Maximize your production line efficiency with our free, comprehensive drawing set for Automatic Welding And Tapping Machinery And Equipment! The convergence of welding and tapping into a single automated system is a revolutionary step in high-speed, high-volume manufacturing. This specialized machinery is engineered to perform precise joining (welding) and threading (tapping) operations sequentially or simultaneously, drastically reducing cycle times and eliminating material handling between processes.

This indispensable drawing package provides the necessary technical details—from the structural framework to the automated indexing tables and the synchronized control systems for both the welding head and the tapping unit. Engineers, fabricators, and students will find these detailed, CAD-ready drawings invaluable for research, system integration, or building a custom automation solution. We understand the critical need for reliable, accurate technical documentation in advanced manufacturing. Stop settling for low-quality references. Download this powerful design resource today to gain a competitive edge and ensure your projects benefit from the very best in automated machine design. Secure your free copy now and leap forward in manufacturing excellence!

Key Features:

- Integrated Process Flow: Shows the seamless design integration of the automated welding station and the multi-spindle tapping station.

- Synchronized Motion Control: Details the mechanisms for precise component alignment and synchronized movement for both joining and threading operations.

- Component Level Blueprints: Includes detailed blueprints for specialized fixtures, clamping devices, and the transfer/indexing system.

- Utility and Interface Layouts: Provides clear diagrams for pneumatic, electrical, and cooling system interfaces essential for continuous operation.

- Modularity in Design: Highlights the modular assembly approach, allowing for customizable configurations and easier maintenance access.