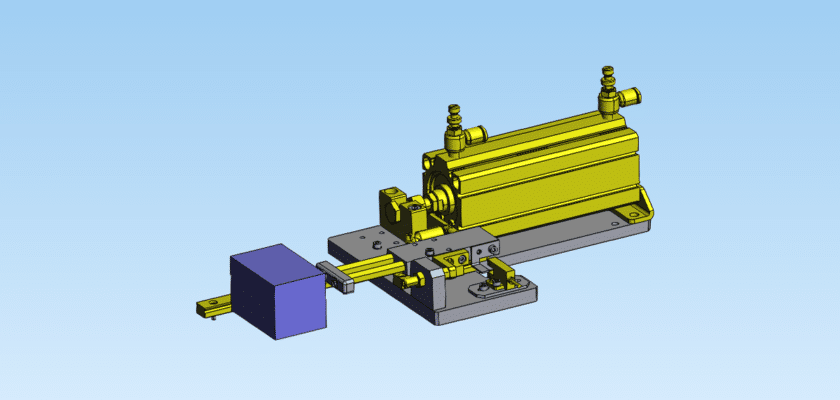

Protect your automation hardware from catastrophic failure with our professional Overload Detection Mechanism For Push Rod drawing. In reciprocating machinery—such as parts ejectors, press feeders, or lid-placers—a “crash” or jam can happen in milliseconds. Without a dedicated sensing mechanism, the drive motor or pneumatic cylinder will continue to apply force until a component bends or snaps. This technical CAD resource provides a blueprint for a spring-loaded “breakaway” or “collapsible” push rod assembly that mechanically disconnects or triggers an E-stop when a pre-set force threshold is exceeded.

The design featured in this package focuses on the Pre-Loaded Compression Spring architecture. The drawing includes detailed layouts for a telescopic rod-in-sleeve design held in place by a calibrated spring. Under normal operating loads, the rod behaves as a single rigid unit. However, if the resistance exceeds the spring tension, the rod collapses (shortens), and an integrated flag trips a proximity sensor to instantly kill power to the drive system. By downloading this file from MechStream, you gain access to a reliable, resettable safety system that is far superior to “shear pins” which require manual replacement after every event.

Our technical documentation prioritizes accuracy and adjustability. The assembly includes a threaded tensioning nut, allowing you to fine-tune the “trip-force” to match your specific application. Whether you are building a delicate electronic pick-and-place machine or a heavy-duty industrial sorter, this drawing provides the exact spring-rate calculations, sensor mounting tolerances, and low-friction bushing specifications required for a professional-grade protection system.

Key Features:

- Instantaneous Signal Feedback: Features a high-speed sensor interface that sends an abort signal to the PLC the moment a collapse is detected.

- Adjustable Trip Threshold: Includes a calibrated spring-tensioner for easy field adjustment of the maximum allowable push force.

- Automatic Reset Capability: Unlike shear pins, this mechanism returns to its original position as soon as the obstruction is removed.

- Telescopic Rigid Alignment: Designed with precision-ground internal guides to ensure the rod does not “wobble” during high-speed normal operation.

- Fail-Safe Mechanical Stop: Includes a hard-stop inside the sleeve to prevent the spring from bottoming out and sustaining permanent damage.