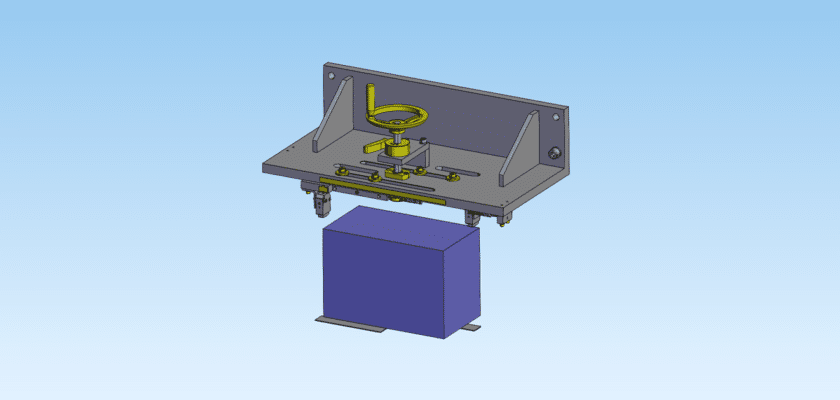

Maintaining the accuracy of width-measuring systems is essential for quality control in industries like textile manufacturing, paper milling, and sheet metal processing. This Synchronous Width Sensor Replacement Assembly CAD drawing provides a high-precision mechanical blueprint for a sensor carriage system designed for rapid maintenance and perfect alignment. In high-speed web handling, sensors must move in perfect synchronicity to measure the distance between edges accurately. This assembly replaces outdated or worn-out fixed mounts with a dynamic, synchronized rail system that allows for quick sensor swaps without losing the calibrated zero-point.

By downloading this technical drawing, you gain access to a modular design that emphasizes “plug-and-play” replacement. The mechanism utilizes a dual-sided rack and pinion or timing belt drive to ensure that when one sensor moves, the opposing sensor mirrors the movement exactly. This mechanical synchronization is critical for preventing skew errors in measurement data. The blueprint includes detailed views of the vibration-dampening mounts, cable management tracks, and the precision linear guides. Whether you are upgrading an existing production line to support new ultrasonic sensors or laser micrometers, this assembly provides the rigid, repeatable framework necessary for industrial-grade measurement accuracy.

Key Features:

- High-Precision Synchronous Drive: Uses a mechanical linkage to ensure perfectly mirrored movement between left and right sensors, eliminating manual calibration errors.

- Quick-Release Sensor Cradles: Features a universal mounting interface that allows for the replacement of sensors in seconds with zero tools required.

- Integrated Calibration Scale: Includes a built-in physical reference scale for immediate visual verification of sensor positions against the digital output.

- Heavy-Duty Linear Bearings: Specifications include low-friction, dust-resistant linear bushings to maintain smooth travel in harsh manufacturing environments.

- Dynamic Cable Management: The design incorporates high-flex cable carriers to protect sensor wiring from fatigue during constant width adjustments.