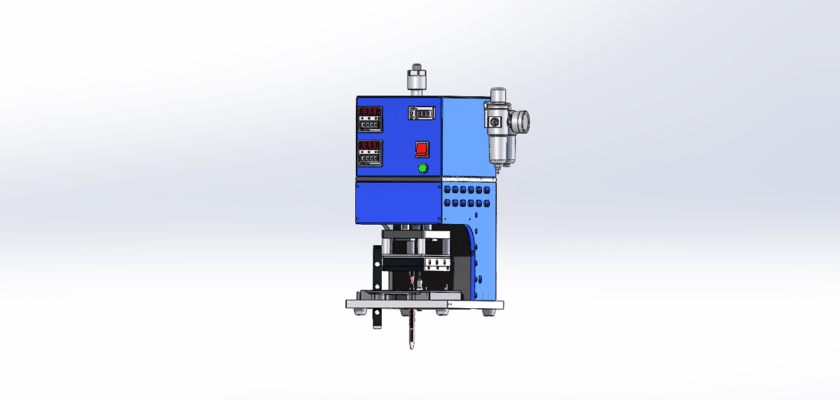

This detailed drawing of the Plastic Hot Melt Riveting Machine illustrates a specialized system engineered for the effective riveting of plastic components using hot melt adhesive technology. Designed to enhance production efficiency and ensure strong, durable bonds, this machine is ideal for applications in the automotive, electronics, and consumer goods industries.

Key Features of the Drawing:

- Advanced Hot Melt Technology: The machine utilizes hot melt adhesive to securely rivet plastic parts, optimizing the bonding process and ensuring high-quality connections.

- Precision Control Mechanisms: Equipped with advanced dispensing and positioning systems, it ensures accurate application and placement of rivets, enhancing overall production quality.

- User-Friendly Interface: The intuitive control panel allows for easy operation, programming, and adjustments, facilitating quick changes for different plastic components and adhesive types.

- Versatile Application Range: Designed to accommodate a variety of plastics and rivet sizes, making it adaptable for diverse manufacturing needs.

- Robust and Durable Construction: Built from high-quality materials, the machine is engineered for reliability and longevity, ensuring optimal performance in demanding industrial environments.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient hot melt riveting solutions in their production processes.