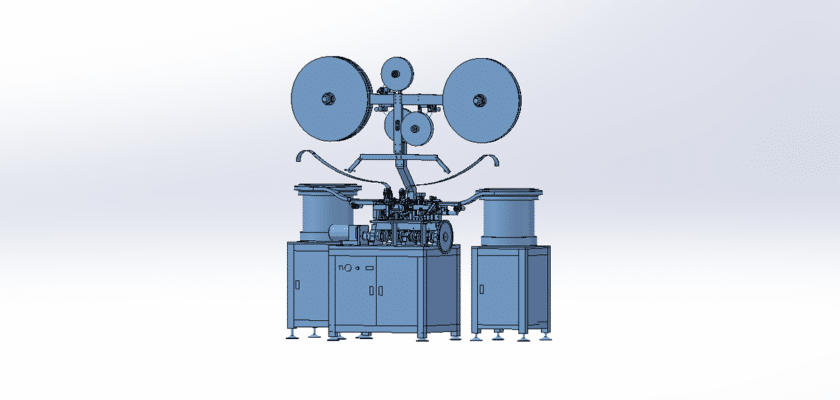

This drawing illustrates the design and layout of a SIM Card Automatic Molding Machine, engineered for efficient production and molding of SIM card components.

Key Features:

- Automated Operation: The machine utilizes advanced automation technology to streamline the molding process, reducing manual intervention and increasing throughput.

- Precision Molding: Designed with high-accuracy molds to ensure that SIM cards are produced to exact specifications, maintaining consistency in size and shape.

- User-Friendly Interface: The control panel features an intuitive interface, allowing operators to easily monitor and adjust settings for optimal performance.

- Safety Mechanisms: Equipped with multiple safety features, including emergency stop buttons and protective covers, ensuring safe operation during production.

- Compact Design: The layout is space-efficient, making it suitable for various production environments while maximizing workflow efficiency.

- Material Handling System: Integrated systems for feeding raw materials and managing finished products, ensuring a smooth flow throughout the production cycle.

- Energy Efficient: Designed to minimize energy consumption while maintaining high performance, contributing to lower operational costs.

This drawing serves as a comprehensive guide for understanding the structure, functionality, and operational processes of the SIM Card Automatic Molding Machine, facilitating effective manufacturing practices in the telecommunications industry.