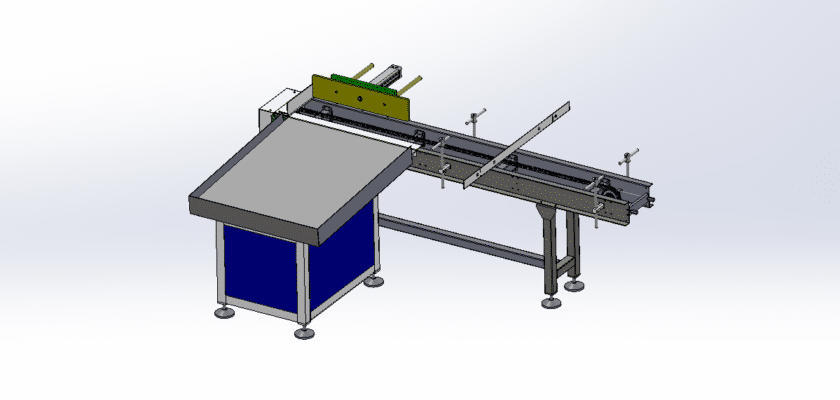

The Automatic Unloading Conveyor Line drawing provides a detailed schematic of a sophisticated conveyor system designed for the automated unloading of materials. This system is particularly useful in logistics, warehousing, and manufacturing environments, where efficiency and speed are critical for handling bulk goods.

Key Features:

- Conveyor Layout: The drawing illustrates the overall configuration of the automatic unloading conveyor, showcasing its length, width, and any necessary inclines or transitions. The design is optimized for seamless integration into loading docks or storage areas, facilitating smooth material flow.

- Belt Specifications: Detailed information on the conveyor belt material is provided, including composition (e.g., heavy-duty rubber, PVC), dimensions, and surface texture. The belt is designed to handle various types of materials while ensuring durability and reliability during operation.

- Automatic Unloading Mechanism: The drawing highlights the automatic unloading features, detailing how the system uses sensors and controls to detect incoming materials and activate unloading processes. This may include tilt mechanisms, gates, or diverters that efficiently direct materials to designated areas.

- Drive System: An overview of the drive mechanism is included, detailing the electric motor, gear systems, and control units that power the conveyor. Specifications regarding motor power, torque ratings, and operational speed are provided to ensure optimal performance.

- Control Systems: Information on the control mechanisms used to operate the conveyor is provided, including user-friendly interfaces for monitoring and adjusting operational parameters, as well as automated controls for initiating unloading sequences.

- Safety Features: Essential safety components, such as emergency stop buttons, safety guards, and sensors for detecting jams or misalignment, are clearly marked to enhance operator safety and ensure compliance with industry standards.

- Support Structure: The robust frame and support components are depicted, emphasizing stability and durability to handle the weight of transported materials. Structural assessments are included to ensure safe operation under various load conditions.

- Maintenance Accessibility: The design includes considerations for easy access to critical components for routine maintenance and inspections, promoting efficient upkeep and minimizing downtime.

This drawing serves as a vital resource for engineers, logistics managers, and maintenance personnel, offering comprehensive insights into the design, implementation, and operation of automatic unloading conveyor systems in diverse industrial applications.