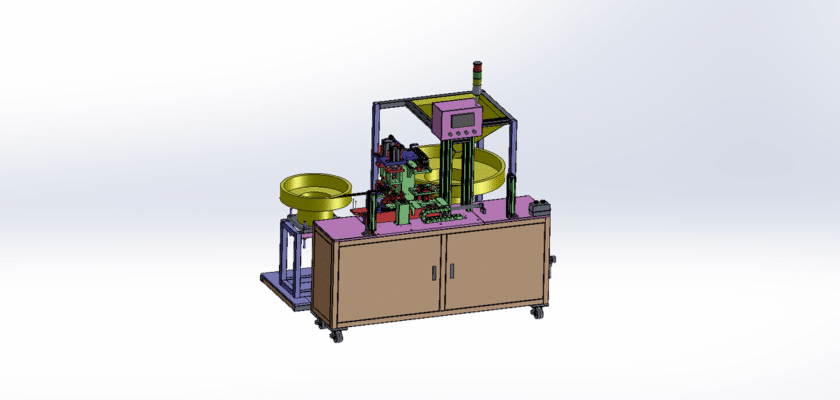

The Fully Automatic Nut Driving Machine is a high-performance assembly tool designed for the efficient and precise fastening of nuts in various industrial applications. This machine automates the nut driving process, significantly enhancing productivity and ensuring consistent quality in manufacturing environments.

Key Features

- Fully Automated Operation: The machine automates the entire nut driving process, from feeding to tightening, reducing manual labor and increasing throughput on assembly lines.

- High Precision Torque Control: Equipped with advanced torque settings, the machine ensures that nuts are tightened to the specified torque, preventing over-tightening and ensuring reliability.

- Versatile Compatibility: Capable of handling a wide range of nut sizes and types, making it suitable for diverse applications in automotive, electronics, and machinery manufacturing.

- User-Friendly Control Panel: A digital interface allows for easy programming, monitoring, and adjustments, enabling operators to optimize performance and respond quickly to changes in production needs.

Components

- Nut Feeding System: An automated mechanism that supplies nuts to the driving unit, ensuring a continuous and efficient flow of fasteners during operation.

- Driving Tool: A high-torque mechanism designed to securely fasten nuts, capable of adjusting to different sizes for versatility in assembly.

- Control System: A PLC-based unit that manages the machine’s operations, allowing for real-time adjustments and monitoring of performance metrics.

- Stable Base Frame: A robust structure that provides stability and minimizes vibrations during operation, enhancing overall reliability and accuracy.

Applications

- Automotive Assembly: Ideal for fastening nuts in vehicle assembly, including engines, chassis, and other critical components where reliability is essential.

- Electronics Manufacturing: Suitable for securing nuts in electronic devices, ensuring precision and quality in assembly.

- Industrial Machinery Production: Efficiently tightens nuts in various machinery, contributing to operational integrity and safety.

Conclusion

The Fully Automatic Nut Driving Machine is an essential tool for modern manufacturing, designed to optimize efficiency and precision in nut fastening processes. Its automated features, high precision, and user-friendly design make it a valuable asset for manufacturers seeking to enhance productivity and maintain high-quality standards. This machine represents a significant advancement in assembly technology, contributing to streamlined operations and improved product reliability.