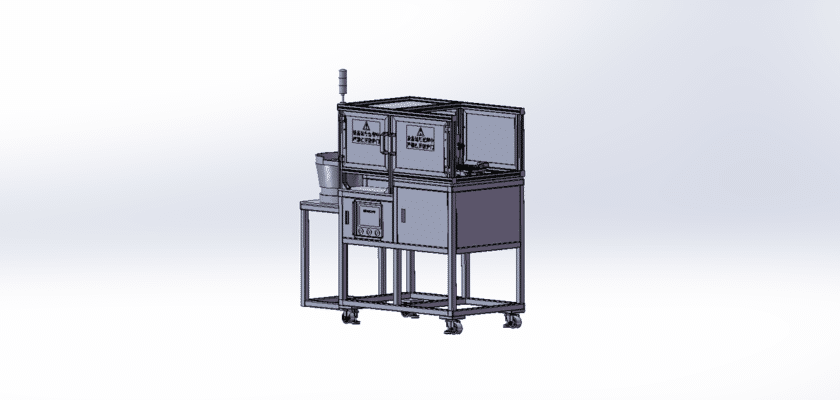

The Nut Automatic Feeding System is designed to streamline the process of feeding nuts into assembly or manufacturing lines with high efficiency and precision. This system automates the feeding of nuts, eliminating manual handling, reducing operational errors, and enhancing production speed. Ideal for industries that require consistent, high-volume feeding of nuts, this system ensures seamless integration with various automated assembly machines.

Key Features:

- Automated Feeding: Eliminates manual labor by automatically feeding nuts into the production line, improving overall efficiency and reducing human error.

- High-Speed Operation: Capable of fast, continuous feeding, ensuring a consistent supply of nuts for uninterrupted production.

- Precise Control: Features accurate orientation and positioning of nuts, ensuring they are fed into the assembly process with minimal misalignment or jamming.

- Versatile Design: Compatible with various nut sizes and types, making it adaptable to a range of industries, including automotive, electronics, and machinery manufacturing.

- Compact and Space-Efficient: Designed for easy installation and operation in limited space, without sacrificing performance or reliability.

- Durable Construction: Built with high-quality materials to ensure long-term durability and minimal maintenance, even in high-volume production environments.

Applications:

- Perfect for automotive assembly lines, electronic product manufacturing, and any production process that requires high-speed, high-accuracy feeding of nuts.

The Nut Automatic Feeding System is an essential component for optimizing fastener feeding in production lines, improving productivity, and ensuring consistent quality in the final assembly.