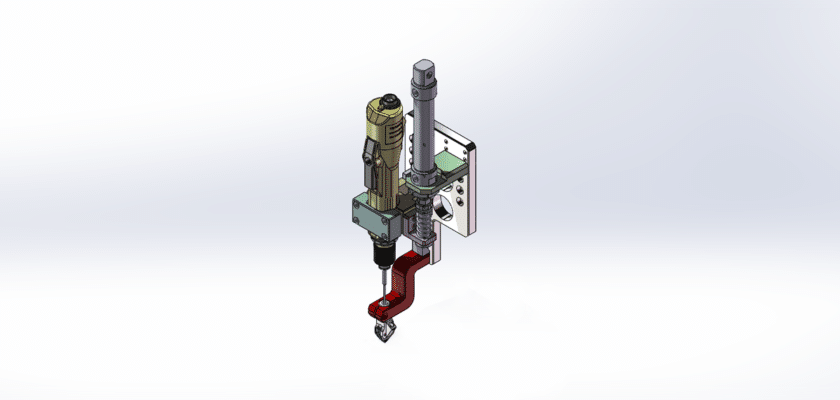

The Single Batch Screwing Machine is an efficient and reliable solution designed for batch processing applications where a fixed number of screws need to be inserted and tightened in a single production run. This machine is ideal for assembly lines requiring a streamlined process for small to medium-sized batches of products that require consistent and secure screw fastening. With its simple design and automated operation, the Single Batch Screwing Machine ensures fast and accurate screw insertion, making it a perfect fit for various industries, including electronics, automotive, and consumer goods manufacturing.

Key Features:

- Single Batch Operation: The machine is optimized for handling a fixed batch of products, making it perfect for smaller, controlled production runs where a predetermined number of screws need to be fastened per cycle.

- Precise Screw Tightening: Equipped with advanced torque control, the Single Batch Screwing Machine ensures each screw is tightened to the exact required specification, preventing issues such as over-tightening or under-tightening.

- Automatic Screw Feeding: The system automatically feeds screws to the tightening mechanism, reducing manual handling and improving production efficiency. This feature minimizes downtime and speeds up the assembly process.

- Adjustable Settings: The machine offers adjustable torque settings and screw size options, allowing for flexibility in handling different types of screws and components for a variety of assembly tasks.

- Compact and Easy to Use: With a simple, user-friendly interface and a compact design, the Single Batch Screwing Machine can be easily integrated into existing production lines and operated by workers with minimal training.

- Batch Counting and Monitoring: The machine is equipped with a batch counter that tracks the number of screws inserted in each cycle, providing operators with real-time feedback and ensuring that no components are missed during assembly.

- Durable and Low Maintenance: Built with industrial-grade materials, the machine is designed for long-term reliability and requires minimal maintenance, making it an ideal solution for high-efficiency production environments.

- Flexible Application: Suitable for a wide range of industries, this machine can be used for assembling various products such as enclosures, electrical components, automotive parts, and more.

- Cost-Effective: The Single Batch Screwing Machine offers a cost-effective solution for batch processing, providing a balance of high-performance automation and affordability for businesses with moderate production volumes.

Applications:

- Ideal for industries that require secure screw fastening in small to medium batches, such as automotive, electronics, consumer goods, and medical device manufacturing.

- Perfect for assembly operations involving products like electrical enclosures, machinery components, devices, and mechanical assemblies that require precise and consistent screw locking.

The Single Batch Screwing Machine provides an effective and automated solution for batch-based screw fastening applications. By combining precise torque control, efficient screw feeding, and simple operation, it ensures fast, reliable, and high-quality assembly for various industries.