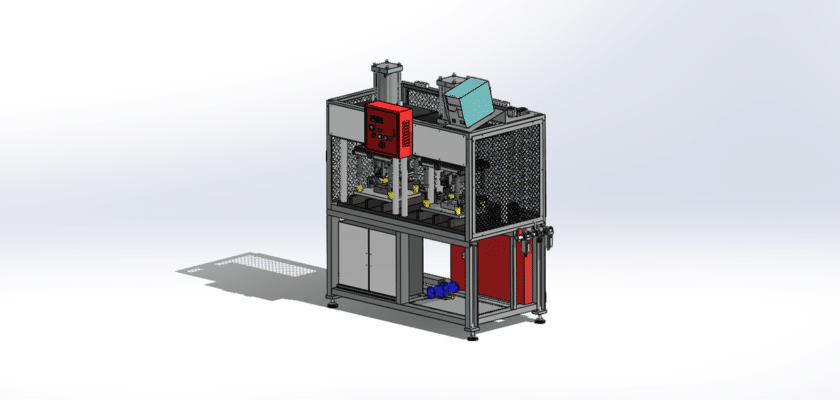

An Intelligent Visual Detection Equipment Drawing is a technical illustration that outlines the components and layout of advanced machinery designed for automated visual inspection and detection of various objects or surfaces.

Key Features:

- Inspection Area: Diagrams showing the designated space where items are placed for visual inspection, often featuring adjustable fixtures or conveyor systems to ensure proper alignment and handling.

- Camera System: Representation of high-resolution cameras or imaging sensors that capture detailed images of the objects being inspected, including their positioning for optimal coverage.

- Lighting Configuration: Details about the illumination systems, such as LED lighting or backlighting, that enhance image clarity and highlight surface features for accurate defect detection.

- Intelligent Processing Unit: Information on the central processing unit that employs algorithms, including machine learning or artificial intelligence, to analyze the captured images and identify defects or anomalies.

- User Interface: Illustrations of the control panel or touchscreen that allow operators to monitor the inspection process, set parameters, and view results in real-time.

- Data Output Systems: Diagrams showing how inspection results are communicated, including digital displays, alerts for identified defects, and connections to data management systems for further analysis.

- Mechanical Handling System: Information about the conveyor belts or robotic arms that transport items through the inspection area, ensuring smooth operation and minimizing handling errors.

- Power Supply: Details regarding the power requirements, including electrical connections and backup systems to ensure reliable operation.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of intelligent visual detection equipment, ensuring efficient quality control and operational effectiveness in various manufacturing and inspection processes.