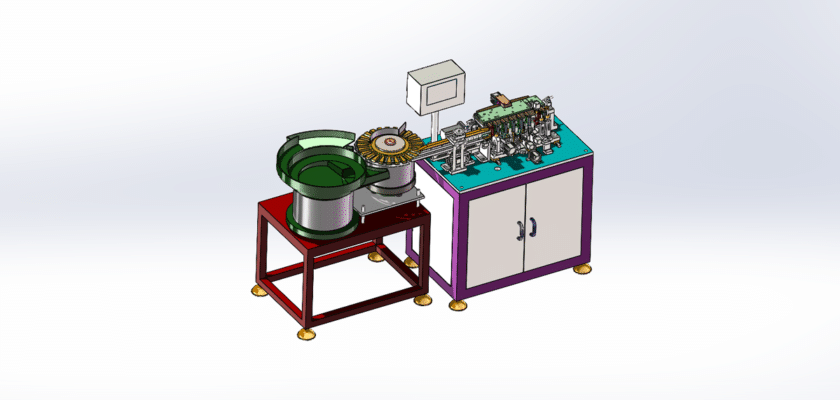

This drawing illustrates a specialized machine designed for the testing and packaging of capacitors in the electronics industry. The system integrates advanced detection technology to ensure quality control and efficient packaging processes.

Key Features:

- Detection Unit: Equipped with sensors that accurately identify capacitor specifications, including capacitance, voltage rating, and polarity. The unit performs real-time testing to ensure each component meets industry standards.

- Automated Handling: The machine features robotic arms or conveyors that automatically transport capacitors from the testing station to the packaging area, minimizing manual intervention and reducing the risk of damage.

- Packaging Station: A high-speed packaging module that utilizes blister or shrink wrap technology to securely package tested capacitors. This unit ensures that the products are protected during shipping and storage.

- User Interface: An intuitive control panel that allows operators to monitor the testing process, adjust parameters, and receive alerts for any defective components.

- Data Logging: The machine includes a data recording system that logs test results for quality assurance and traceability, helping manufacturers maintain compliance with regulatory standards.

- Compact Design: Designed to fit into various production environments, the machine optimizes floor space while maximizing throughput.

Applications:

Ideal for manufacturers in the electronics sector, this machine enhances efficiency in capacitor production, ensuring that only the highest quality components reach the market.