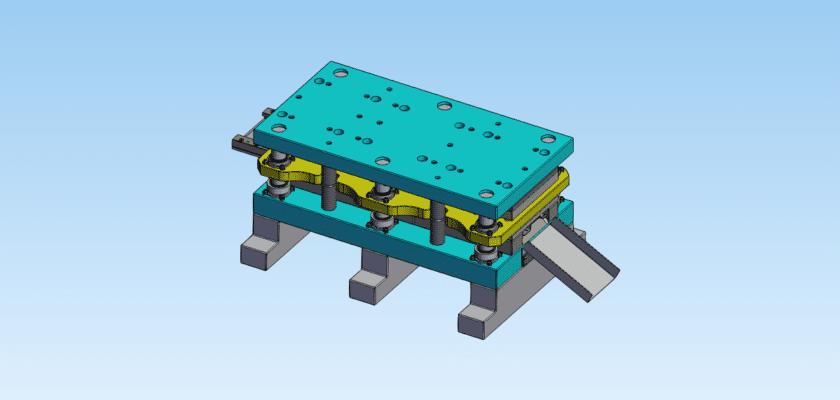

Elevate your manufacturing precision with our comprehensive 160-01 Progressive Die technical drawing. This professional-grade resource is an essential asset for tool and die makers, mechanical engineers, and high-volume production facilities looking to streamline their metal stamping operations. Progressive dies are the backbone of efficient manufacturing, allowing for multiple operations—such as punching, coining, and bending—to be performed at various stations within a single stroke of the press.

By downloading this full documentation, you gain access to a meticulously detailed layout designed for durability and high-speed accuracy. This drawing helps eliminate the guesswork in the design phase, ensuring that material feed rates and station sequences are perfectly synchronized. Whether you are building a new tool from scratch or analyzing station layouts for optimization, this technical file provides the structural clarity required for modern industrial standards.

The 160-01 model is specifically engineered to handle complex geometries while maintaining tight tolerances over long production runs. Utilizing this drawing ensures that your tooling team has a clear roadmap for assembly, maintenance, and part replacement, ultimately reducing downtime and maximizing output.

الميزات الرئيسية:

- Complete Station Layout: Detailed visualization of the entire stamping sequence from strip feed to final part ejection.

- High-Precision Tolerances: Engineered specifications that meet rigorous industrial standards for consistent part quality.

- Optimized Strip Design: Focuses on minimizing material waste (scrap) to improve cost-efficiency during production.

- Robust Component Specs: Includes clear detailing for punches, die plates, and guide pillars to ensure long-term tool life.