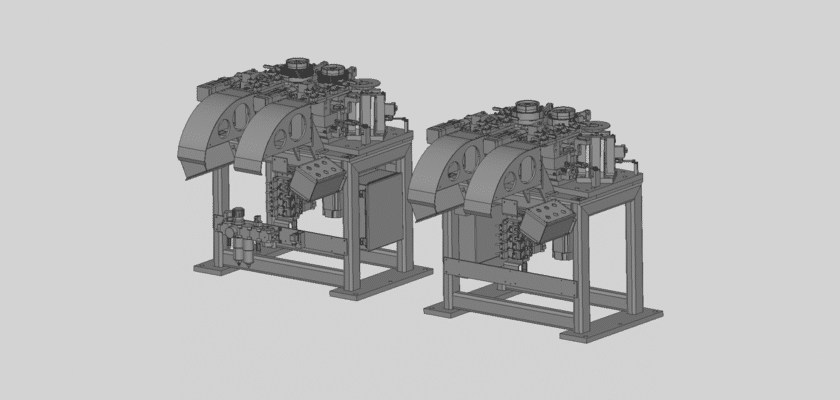

انتقل بتصنيعك إلى المستوى التالي مع رسومات نظام التجميع التلقائي لرأس الأسطوانة مجانية! يوفر هذا المورد الأساسي مخططات بناء نظام تجميع عالي السرعة ودقيق، مصمم لربط الأجزاء الأسطوانية. بخلاف طرق الربط التقليدية، يستخدم نظام رأس الأسطوانة سلسلة من البكرات الدوارة لتشكيل تجعيد أو شفة على حافة القطعة، وتثبيتها داخل قطعة أخرى. تُعد هذه العملية غير التصادمية مثالية لإنشاء وصلات متينة وسلسة في منتجات مثل المحامل والأنابيب والصمامات الهيدروليكية دون إتلاف المواد. رسوماتنا التفصيلية مثالية للمهندسين الميكانيكيين، ومتخصصي الأتمتة، والطلاب الذين يسعون إلى فهم آليات العمل الداخلية لتكنولوجيا التجميع الحديثة. بتنزيل هذه المخططات المجانية، ستكتسب المعرفة اللازمة لبناء نظام يُحسّن سرعة إنتاجك، ويضمن جودة ثابتة، ويقلل من الحاجة إلى العمل اليدوي. ارتقِ بعملية التجميع لديك وحقق نتائج فائقة مع هذا الحل الفعال للأتمتة.

الميزات الرئيسية:

- تشكيل الأسطوانة الدقيقة: يوضح التصميم كيفية عمل العديد من الأسطوانات في انسجام تام لتشكيل وصلة دائمة بلطف ودقة، مما يضمن جودة ثابتة ويزيل إجهاد المواد.

- تشغيل عالي السرعة: تم تحسين النظام لأوقات الدورة السريعة، مما يسمح بزيادة كبيرة في معدل الإنتاج مقارنة بالتجميع اليدوي التقليدي أو التجميع المعتمد على الضغط.

- التعامل مع الأجزاء متعددة الاستخدامات: تتضمن الرسومات مخططات لآليات التغذية والتثبيت القابلة للتكيف، مما يتيح للنظام التعامل مع مجموعة متنوعة من أحجام الأجزاء الأسطوانية والمواد.

- تجميع غير مؤثر: يتجنب هذا التصميم التأثيرات القوية الناتجة عن التثبيت أو الضغط التقليدي، مما يجعله مثاليًا للأجزاء الحساسة أو التطبيقات حيث تكون سلامة المواد ذات أهمية قصوى.

- معيارية وقابلة للتطوير: يتيح الهيكل المعياري للنظام التكامل السهل مع خطوط الإنتاج الحالية ويوفر المرونة اللازمة لإضافة المزيد من محطات العمل مع نمو متطلبات الإنتاج لديك.