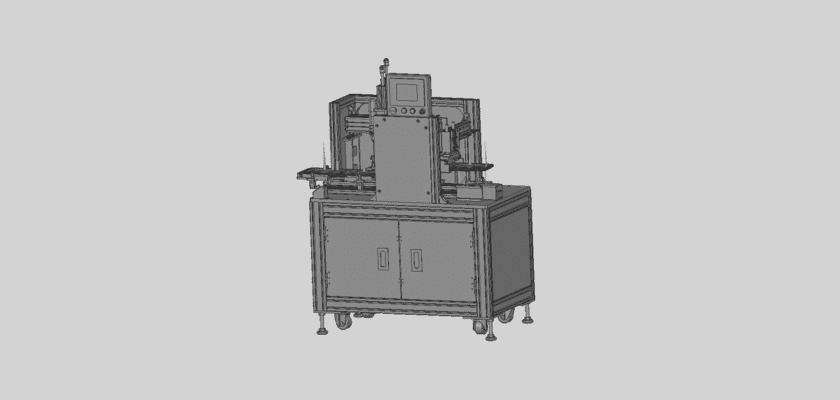

إن keyboard screw locking machine is an essential piece of equipment in the automated assembly of keyboards and other small electronic devices. It automates the tedious and time-consuming process of fastening screws, ensuring precision, speed, and consistency that human hands cannot match. This machine is a game-changer for manufacturers, significantly reducing labor costs and eliminating human error in the crucial assembly phase. We are thrilled to offer a detailed, free drawing of this technology.

This set of comprehensive engineering drawings provides a complete look at the inner workings of an automated screw locking machine. The schematics detail how the machine automatically feeds, positions, and tightens screws with a preset torque, ensuring perfect fastening every time. Our drawing package is an invaluable resource for students of mechanical engineering and automation, as well as for professionals looking to optimize their production lines. The files are provided in multiple formats for easy integration with your preferred CAD software, making them a perfect starting point for your next project or a powerful educational tool.

الميزات الرئيسية:

- Automated Screw Feeding: The drawings detail the vibrating bowl feeder and air-blowing or suction systems that deliver screws precisely to the driver head, eliminating manual handling.

- Robotic Positioning System: The plans illustrate the sophisticated XYZ axis platform and PLC-controlled robotics that accurately position the screw head over each hole, regardless of the product’s layout.

- Torque and Quality Control: The design includes integrated torque sensors and detection features that prevent over-tightening, stripping, or the omission of screws, ensuring a flawless final product.

- تشغيل عالي السرعة: The drawings showcase the efficient design that allows for rapid screw fastening, often completing the task in under two seconds per screw, drastically increasing production efficiency.

- Multi-Product Adaptability: The modular nature of the design allows for easy reconfiguration and programming to accommodate a variety of product sizes and screw patterns, making it highly versatile for different manufacturing needs.