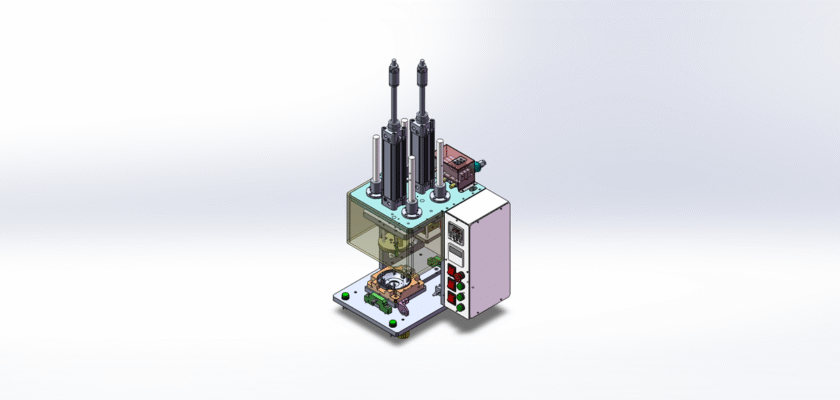

أ riveting and hot-melt machine is a specialized piece of equipment designed to create strong, permanent bonds in materials, particularly for joining plastic components or plastic to metal. This advanced technology combines the principles of traditional riveting with the modern application of heat to soften and deform a plastic stud or boss, creating a clean, secure, and non-detachable joint. This process is essential in industries like electronics, automotive, and medical device manufacturing where precise, clean, and durable assembly is critical. Unlike traditional riveting with metal fasteners, this method uses the thermoplastic properties of the material itself, eliminating the need for additional consumables like screws or adhesives. The detailed drawings offer an unparalleled view into the intricate mechanisms, from the thermal control system to the pneumatic press. This free resource is perfect for mechanical engineers, designers, and students looking to explore cutting-edge automation technology and understand the mechanics behind modern joining processes.

الميزات الرئيسية:

- Dual-Process Integration: The drawing illustrates how the machine seamlessly combines a heating element for hot-melt forming with a press for cold riveting, providing a versatile solution for a wide range of assembly tasks.

- تحكّم حراري دقيق: The blueprints showcase a sophisticated system for controlling the temperature of the riveting head, ensuring the plastic is softened just enough for perfect deformation without being damaged or scorched.

- تطبيق متعدد الاستخدامات: The design is engineered to work with various plastic types and can be adapted to join plastic parts to other materials like metal sheets, offering a highly flexible solution for mixed-material products.

- Automated and Consistent Operation: The drawings highlight the machine’s automated workflow, which ensures consistent results with every cycle, significantly reducing labor costs and improving product quality and uniformity.