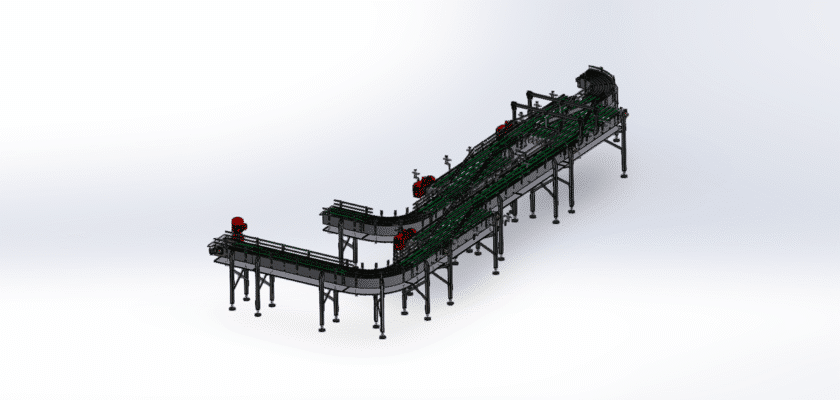

أ roller assembly line is a type of conveyor system that uses a series of rollers to transport products and materials from one workstation to another. This simple yet highly effective technology is the backbone of countless manufacturing and warehousing operations. By providing a smooth, continuous flow of goods, roller assembly lines dramatically increase efficiency, reduce manual handling, and streamline production workflows. The system is highly versatile and can be configured in various ways, including straight sections, curves, and inclines, to fit a wide range of facility layouts and applications. This comprehensive drawing provides a detailed blueprint of a professional-grade roller assembly line. It’s an invaluable resource for mechanical engineers, logistics planners, and students who want to understand the design principles of modern material handling systems. By using these free plans, you can gain a deeper understanding of how these lines are engineered to handle various loads and optimize industrial processes.

الميزات الرئيسية:

- تصميم معياري: The drawing highlights a modular construction, allowing for easy expansion, reconfiguration, and customization to meet the specific needs of different production or warehousing environments.

- Variable Speed Control: The blueprints detail a system that can be equipped with variable speed motors, enabling precise control over the flow of materials to match the pace of the assembly process.

- هيكل متين: The design features heavy-duty rollers and a robust frame, ensuring the assembly line can withstand continuous, high-volume use and transport a wide range of weights and sizes.

- صيانة منخفضة: The plans show a simple and reliable design with minimal moving parts, making it easy to maintain and reducing the likelihood of costly downtime.

- ميزات السلامة المتكاملة: The drawings include schematics for safety guards and emergency stop buttons, ensuring a safe working environment for all operators.