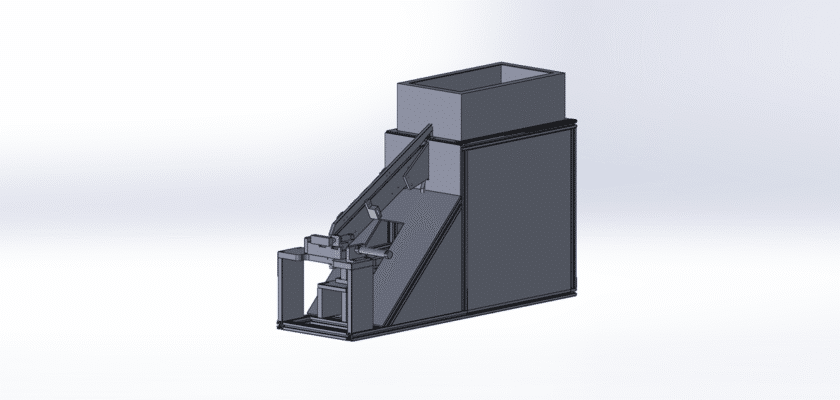

أ screw feeding mechanism is an essential tool in automated manufacturing and assembly lines, designed to dispense screws individually and accurately to a robotic arm or operator. This device is critical for high-speed production, as it eliminates the need for manual screw handling, which is slow and prone to error. By automating the feeding process, manufacturers can significantly increase efficiency, reduce labor costs, and ensure a consistent and reliable assembly workflow. This comprehensive drawing provides a detailed blueprint of a professional-grade screw feeding mechanism, showcasing its intricate mechanical and electronic components. This free resource is invaluable for engineers, designers, and students in automation and robotics who want to understand the principles of automated part handling. The plans offer deep insights into how screws are sorted, oriented, and delivered to the exact point of assembly, making it an excellent educational tool for designing your own automated systems.

الميزات الرئيسية:

- High-Speed Delivery: The design is engineered for rapid, consistent screw feeding, ensuring a continuous supply to the assembly point without bottlenecks.

- Precise Orientation: The blueprints detail the internal sorting system that correctly orients each screw, presenting it with the head or thread facing the right direction for easy pickup by a robotic gripper or screwdriver.

- Versatile Compatibility: The mechanism can be easily adjusted to accommodate different screw sizes and types, from micro-screws to larger fasteners, making it a flexible solution for various product lines.

- Robust and Reliable: The drawing highlights a durable design built to withstand the continuous, high-volume demands of industrial assembly, ensuring long-term operational reliability with minimal maintenance.