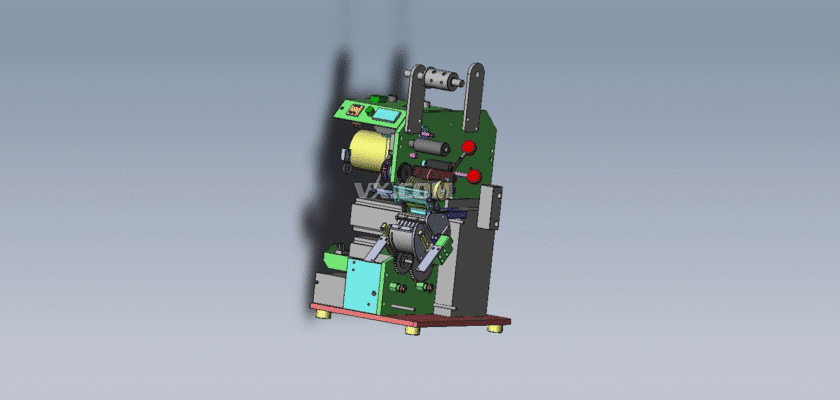

أ tape rolling machine is a specialized piece of equipment used to precisely wind and rewind various types of adhesive tapes, films, or ribbons onto cores. This machine is essential in industries like packaging, electronics, and medical device manufacturing, where consistent tension, clean edges, and accurate length are critical for product quality. Unlike manual methods, an automated tape rolling machine ensures uniformity and significantly increases production speed. This comprehensive drawing, available for free download, provides a detailed blueprint of a professional-grade tape rolling system. It’s an invaluable resource for mechanical engineers, industrial designers, and students who want to understand the intricate mechanical and electrical systems that enable high-precision winding. The plans illustrate the essential components, from the motor and tension control system to the winding arbor and cutting mechanism, giving you the knowledge to design, build, or simply gain a deeper understanding of this crucial industrial equipment.

الميزات الرئيسية:

- Precision Tension Control: The drawing details a sophisticated braking or clutch system that maintains consistent tension on the tape throughout the winding process, preventing wrinkles, stretching, and ensuring a uniform roll.

- Variable Speed Winding: The blueprints showcase a motor with a speed control system, allowing operators to adjust the winding speed to match the material type and desired roll specifications.

- Automated Cutting & Slitting: The design includes an integrated cutting mechanism that precisely slits the tape or cuts it to a specific length after the roll is completed, all with a single machine.

- Versatile Core & Material Handling: The machine is engineered with an adjustable arbor that can accommodate a variety of core sizes and is designed to handle different tape widths and materials, making it a flexible solution for various applications.