Dive into the world of dairy processing with our comprehensive layout drawing for a معدات إنتاج الجبن line. This schematic is an essential tool for artisan cheesemakers, food engineers, and entrepreneurs looking to design or understand the workflow of a small to medium-scale cheese-making facility. Our free drawing provides a clear and logical arrangement of the critical machinery needed to transform raw milk into finished cheese, emphasizing an efficient and hygienic process flow.

This layout serves as a foundational blueprint for facility planning, helping you visualize the entire production cycle, from milk reception to the final pressing stage. Understanding the placement and interconnection of each piece of equipment is crucial for optimizing space, ensuring food safety, and maximizing productivity. Download this invaluable resource for free to kickstart your planning, enhance your engineering knowledge, or streamline your existing operations.

الميزات الرئيسية:

- Milk Reception & Pasteurization: The drawing includes a standard milk reception tank and a pasteurizer unit, illustrating the first critical step in ensuring product quality and safety.

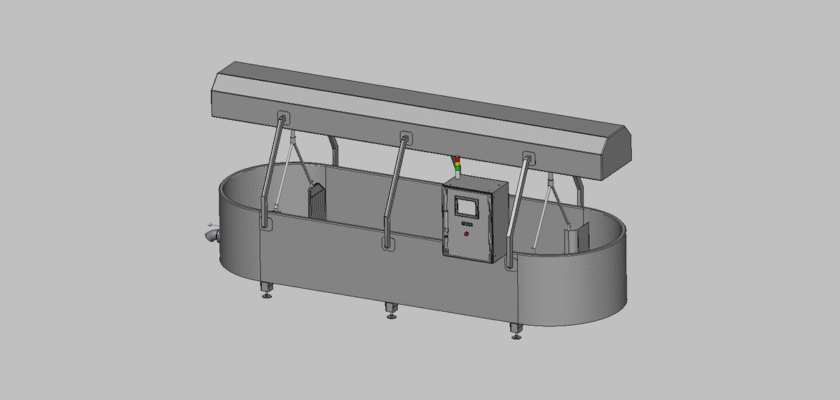

- Jacketed Cheese Vat: At the heart of the layout is a detailed cheese vat, complete with an agitator/cutter mechanism and a heating jacket for precise temperature control during coagulation and cooking.

- Curd Draining & Pressing System: Features a clear layout of draining tables for efficient whey separation, as well as a series of cheese presses essential for forming and texturing the curd.

- Process Flow Schematic: The drawing illustrates the logical flow with sanitary piping and pump connections between the major pieces of equipment, providing a complete overview of the operational sequence.