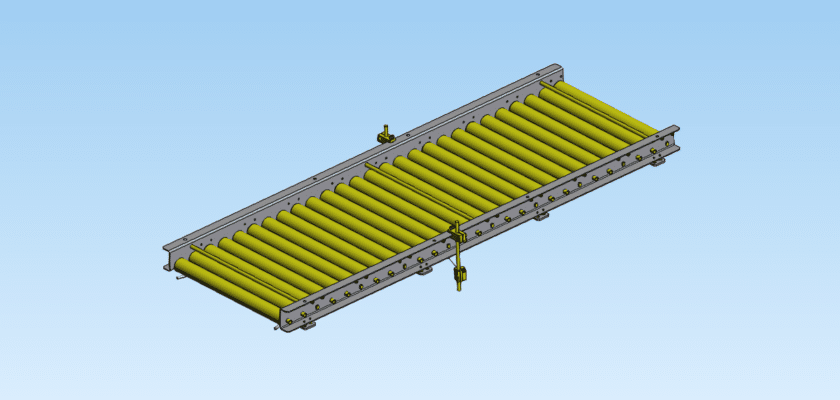

إن Workpiece Pass Confirmation Process is a vital mechanical and electronic safety gate used in automated production lines to verify that a part has successfully completed a specific operation before advancing to the next stage. This mechanism prevents “blind” processing, ensuring that downstream machines do not attempt to work on a missing, misaligned, or defective part. By integrating physical detection with signal feedback, this process acts as a localized quality controller, significantly reducing the risk of machine crashes and serialized production errors in high-speed environments.

By downloading this detailed الرسم, you will gain access to a complete assembly layout for a standardized confirmation station. The CAD data includes the mechanical mounting for various sensor types—such as proximity probes, laser gates, and mechanical limit switches—alongside the physical “trigger” mechanisms required for reliable detection. This design is particularly useful for system integrators who need to build a robust “handshake” between independent machine cells. The blueprints provide the necessary clearances and adjustment ranges to handle different workpiece profiles, ensuring that your confirmation logic remains accurate even if part specifications change. Implement this proven verification process to safeguard your equipment and maintain a 100% “good part” flow throughout your facility.

الميزات الرئيسية:

- Dual-Sensor Redundancy: Designed with mounting points for multiple sensor types to eliminate “false positives” in the detection cycle.

- Adjustable Detection Height: Features a sliding bracket system to align sensors perfectly with the critical features of varying workpieces.

- High-Speed Signal Response: Optimized mechanical trigger geometry to ensure the sensor is activated and deactivated within milliseconds.

- Environmental Shielding: The drawing includes specifications for protective covers to prevent dust, oil, or metal shavings from interfering with the sensors.

- Seamless PLC Integration: Provides a standardized layout for cable management and junction boxes to simplify the electrical setup.