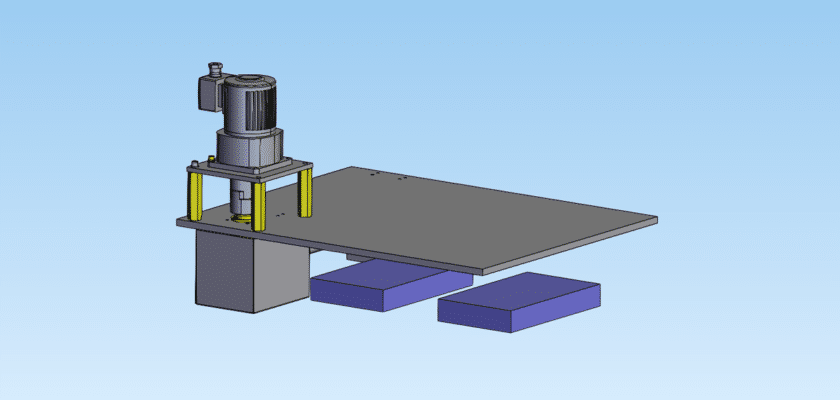

Optimize your facility layout with our professional Right-Angle Configuration Mechanism for conveyor drive units. In modern material handling, space is a premium; a right-angle drive allows the motor to be positioned parallel to the conveyor frame, significantly reducing the machine’s footprint compared to traditional inline configurations. This technical الرسم provides a complete architectural blueprint of the gearbox and mounting assembly required to redirect torque through a 90-degree turn without losing mechanical efficiency.

By downloading this resource, you gain a deep understanding of the internal gear mesh and shaft alignment necessary for smooth, quiet operation. The file details the integration of bevel or worm gearing, heavy-duty bearing housings, and the torque arm assembly that stabilizes the drive under load. This الرسم is particularly valuable for engineers designing modular conveyor systems for logistics, food processing, or automotive assembly lines. At MechStream, we provide these high-fidelity CAD assets for free, ensuring you have the precise dimensions and clearance data needed to integrate powerful drive units into tight spaces. Download this mechanism today to enhance your automation projects and streamline your conveyor design process.

الميزات الرئيسية:

- Compact Footprint Design: Engineered to minimize lateral protrusion, allowing conveyors to be placed closer to walls or other machinery.

- High-Torque Bevel Gearing: Features detailed tooth profiles designed for high-efficiency power transmission and minimal backlash.

- Universal Mounting Flange: A standardized interface that accommodates a wide variety of NEMA or IEC motor frames.

- Integrated Heat Dissipation: Fin-cooled housing design included in the drawing to manage thermal loads during continuous operation.

- Robust Vibration Dampening: Specifications for specialized mounting bushings that reduce noise and prevent mechanical fatigue in the conveyor frame.