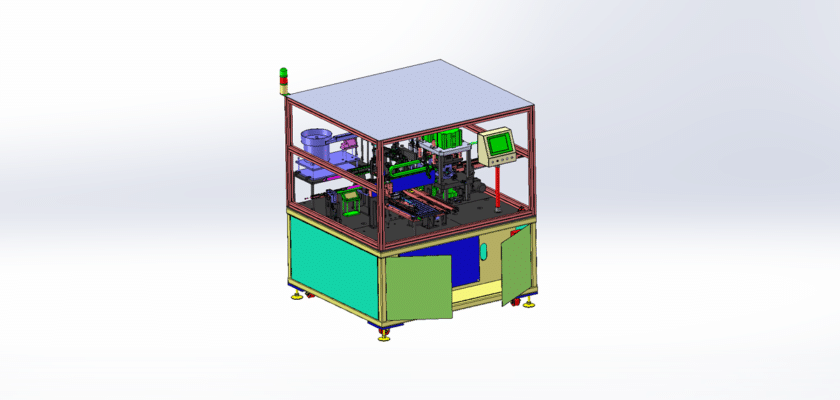

This detailed drawing of the Automatic Assembly Machine for Inductors showcases a specialized system designed for the efficient and precise assembly of inductor components used in various electronic applications. Ideal for manufacturers in the electronics and telecommunications industries, this machine enhances production efficiency while ensuring high-quality outputs.

Key Features of the Drawing:

- Automated Assembly Process: The machine utilizes advanced automation technology to minimize manual intervention, significantly increasing throughput and consistency in the assembly of inductor components.

- High Precision Handling: Equipped with precision mechanisms for aligning and positioning parts, ensuring accurate assembly that meets stringent quality standards and performance specifications.

- User-Friendly Control Interface: The intuitive control panel allows operators to easily program and monitor the assembly process, facilitating quick adjustments for different inductor designs and specifications.

- Versatile Compatibility: Designed to accommodate various types and sizes of inductors, making it adaptable for diverse applications across the electronics sector.

- Integrated Quality Control: Features real-time monitoring and inspection systems to ensure that each assembled inductor meets quality standards, reducing defects and enhancing overall reliability.

- Robust and Durable Construction: Built from high-quality materials, the machine is engineered for longevity and reliability, ensuring optimal performance in demanding industrial environments.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient assembly solutions for inductors in their production lines.