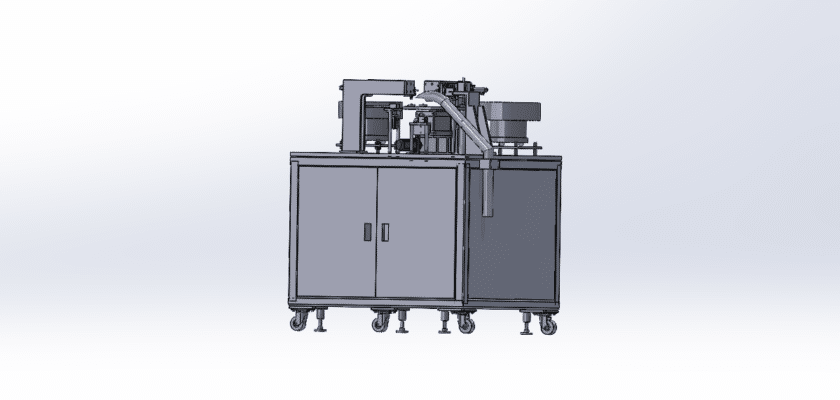

This detailed drawing of the Automatic Assembly Pressing Equipment showcases a highly specialized system designed for the efficient assembly and pressing of components in various manufacturing applications. Ideal for industries such as automotive, electronics, and appliances, this equipment enhances production efficiency while ensuring consistent quality in assembly processes.

الميزات الرئيسية للرسم:

- Automated Pressing Mechanism: The equipment utilizes advanced automation technology to perform precise pressing operations, significantly reducing manual intervention and increasing overall production efficiency.

- التحكم عالي الدقة: Equipped with hydraulic or pneumatic systems, the pressing equipment ensures accurate application of force, critical for achieving tight tolerances and proper component alignment.

- واجهة تحكم سهلة الاستخدام: The intuitive control panel allows operators to easily program and monitor the assembly and pressing processes, facilitating quick adjustments for different product specifications.

- نطاق تطبيق متعدد الاستخدامات: Designed to accommodate various component sizes and configurations, making it adaptable for diverse assembly tasks across multiple industries.

- ميزات السلامة المتكاملة: The equipment includes comprehensive safety mechanisms to protect operators during operation, ensuring compliance with industry safety standards.

- بناء قوي ودائم:تم تصنيع المعدات من مواد عالية الجودة، وتم تصميمها لتكون طويلة الأمد وموثوقة، مما يضمن الأداء الأمثل في بيئات الإنتاج الصعبة.

This drawing serves as an essential reference for engineers and manufacturers seeking to implement effective and efficient assembly and pressing solutions in their production lines.