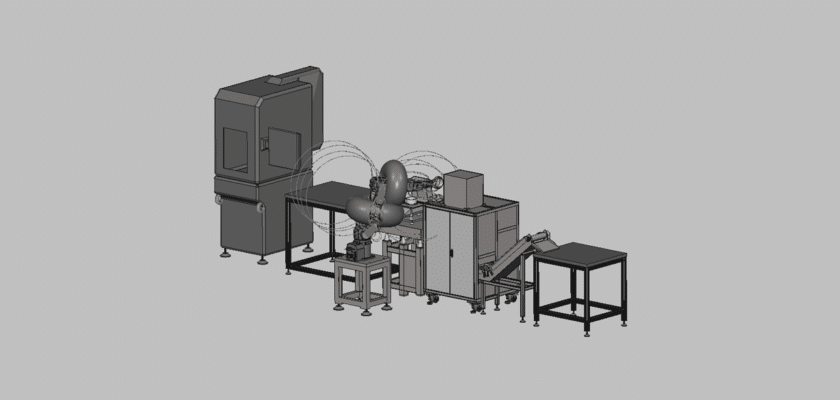

A Visual Detection Automation Drawing is a technical illustration that outlines the components and layout of an automated system designed for visual inspection and detection of products or components in a manufacturing environment. This type of system enhances quality control and operational efficiency.

الميزات الرئيسية:

- منطقة التفتيش: Diagrams showing the designated space where products are positioned for visual detection, featuring fixtures or conveyors that securely hold and transport items during inspection.

- نظام الكاميرا: Representation of high-resolution cameras or imaging sensors strategically placed to capture detailed images of the products, ensuring optimal coverage for accurate detection.

- إعداد الإضاءة: Details about the illumination system, such as LED lights or backlighting, designed to enhance visibility and highlight features of the products for more effective inspection.

- وحدة معالجة الصور: Information on the processing unit that analyzes the images captured by the cameras, using algorithms to identify defects, measure dimensions, and assess overall quality.

- وحدة التحكم: Information on the central processing unit that manages the automation of the detection process, coordinating the camera operation, lighting, and data analysis.

- واجهة المستخدم:رسوم توضيحية للوحة التحكم أو شاشة اللمس التي تسمح للمشغلين بمراقبة عملية التفتيش، وضبط الإعدادات، وعرض النتائج في الوقت الفعلي.

- أنظمة إخراج البيانات: Diagrams showing how inspection results are logged and communicated, including digital displays for immediate feedback, data storage for quality analysis, and connections for reporting to external systems.

- الإطار الميكانيكي: Information about the structural components that support the visual detection system, ensuring stability and precision during operation.

- مزود الطاقة:تفاصيل بشأن متطلبات الطاقة، بما في ذلك التوصيلات الكهربائية وأي أنظمة احتياطية للحفاظ على التشغيل الموثوق به.

This drawing serves as a comprehensive reference for engineers and technicians involved in the design, assembly, and maintenance of visual detection automation systems, ensuring high standards of quality control and efficiency in manufacturing processes.