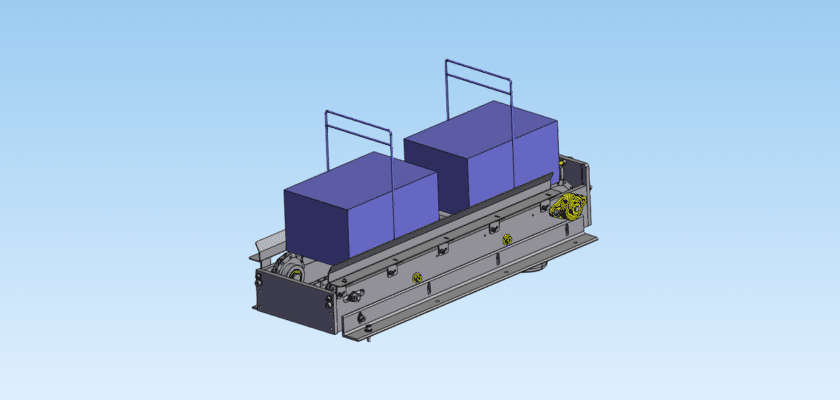

Optimize your specialty transport systems with our professional Basket Conveying Chain Conveyor drawing. Unlike standard flat-belt systems, basket-style chain conveyors are specifically engineered to secure parts during steep inclines, high-speed travel, or cleaning processes where drainage is required. This detailed technical blueprint provides the foundational engineering for a robust dual-strand chain system equipped with custom-mounted basket carriers, making it an ideal choice for automotive parts washing, food processing, or dip-coating applications.

The design focuses on the synchronization of the drive sprockets and the stabilization of the baskets to prevent swaying or spilling during operation. By downloading this drawing from MechStream, you gain access to critical assembly details, including the reinforced chain attachments, track profiles, and motor drive configurations. The geometry is meticulously planned to ensure smooth transitions around curves and sprockets, minimizing mechanical vibration and extending the fatigue life of the chain links.

Integrating this basket conveying solution into your facility allows for the efficient movement of bulky or irregularly shaped items that cannot be transported on traditional surfaces. The drawing is provided in high-fidelity CAD formats, allowing for easy modification of basket dimensions or pitch to suit your specific production requirements. Whether you are building a continuous furnace line or a vertical lift system, this resource provides the industrial-grade precision needed for a successful build.

الميزات الرئيسية:

- High-Stability Basket Mounts: Features a specialized attachment link design that keeps baskets level even during vertical transitions.

- Dual-Strand Synchronization: Engineered drive shaft details that ensure both chains move in perfect harmony to prevent carrier tilting.

- Open-Mesh Basket Design: The drawing includes specifications for perforated or wire-mesh baskets to facilitate fluid drainage or airflow.

- Tensioning System Integration: Includes a dedicated take-up unit design to maintain optimal chain tension and prevent sagging over long spans.

- Heavy-Duty Sprocket Geometry: Detailed tooth profiles optimized for industrial roller chains to reduce noise and mechanical wear.