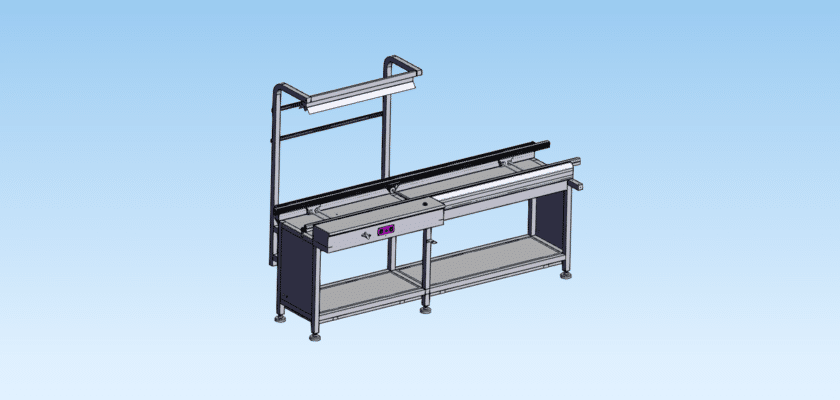

Optimize your air handling systems with our high-quality technical drawing for a Blower Sheet Metal Structure. This design is specifically engineered for industrial and commercial ventilation applications where durability and aerodynamic efficiency are paramount. Centrifugal blower housings require precise geometric curves—often referred to as volute or scroll shapes—to effectively convert kinetic energy into static pressure. Our drawings provide the exact flat-pattern layouts and bend sequences needed to manufacture these complex housings using standard sheet metal fabrication techniques.

By downloading this drawing, you gain access to a professionally vetted design that accounts for material thickness, bend deductions, and structural reinforcement. The blueprint includes detailed views of the inlet cone, the scroll housing, and the discharge flange, ensuring a seamless fit with existing ductwork or motor assemblies. This resource is invaluable for shops utilizing CNC laser, waterjet, or plasma cutting, as the precise dimensions help minimize material waste and reduce assembly time during the welding or riveting process.

Whether you are designing a custom extraction system for a workshop or replacing a worn-out industrial fan casing, this sheet metal structure provides the mechanical foundation you need. The design focuses on minimizing vibration and noise by incorporating stiffening ribs and optimized mounting points. Download the Blower Sheet Metal Structure documentation today to ensure your ventilation projects meet the highest standards of mechanical performance and structural integrity.

الميزات الرئيسية:

- Aerodynamic Scroll Design: Engineered with a precise volute curve to maximize airflow efficiency and pressure output.

- Precision Flat-Pattern Layouts: Includes accurate 2D templates with clear bend lines for easy CNC cutting and hydraulic press brake forming.

- Reinforced Housing: Features integrated stiffening zones to prevent oil-canning and reduce operational noise and vibration.

- Standardized Flange Interfaces: Designed with universal bolt patterns for easy connection to motors and industrial ducting systems.

- Material Versatility: Specifications are adaptable for various gauges of galvanized steel, stainless steel, or aluminum depending on the environment.