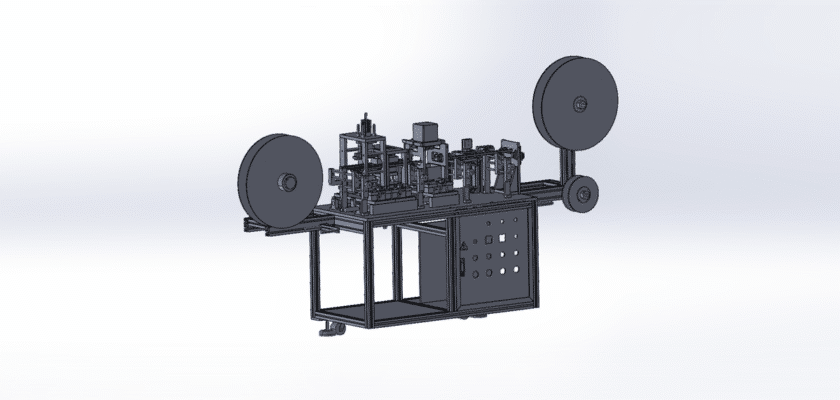

Unleash the potential of your electronics manufacturing process with our free technical drawing of a Carrier Tape Forming Machine. This comprehensive and detailed الرسم is an essential resource for engineers, students, and manufacturers looking to optimize their production lines. Carrier tapes are the backbone of modern automated assembly, providing a secure and precise way to handle delicate electronic components like ICs, resistors, and capacitors. This machine, based on the industry-standard thermoforming method, is designed to create custom pockets that ensure components are protected and perfectly aligned for high-speed pick-and-place machines.

The document provides a clear, step-by-step schematic of the entire forming process, from raw material feeding and precise heating to the final pocket forming and slitting stages. By studying this drawing, you’ll gain an in-depth understanding of the mechanical and automated systems that make high-volume, high-precision carrier tape production possible. This isn’t just a simple diagram; it’s a blueprint for efficiency, highlighting the intricate engineering behind seamless component packaging. Download this الرسم الحر today to improve your design skills and master the principles of industrial automation.

الميزات الرئيسية:

- Precision Pitch Control: The design emphasizes a synchronized feeding mechanism to ensure consistent pocket spacing, adhering to strict industry standards (EIA-481).

- Modular Tooling: The plans show a versatile system that can accommodate different pocket sizes and tape widths, enabling flexible and customizable production runs with minimal downtime.

- Integrated Slitting and Winding: The drawing details the final stages where the formed tape is trimmed to the correct width and neatly wound onto reels, showcasing an efficient end-to-end process.

- مناولة المواد الآلية: Gain insight into the automated systems for feeding raw material and collecting the finished carrier tape, which are critical for continuous and uninterrupted operation.