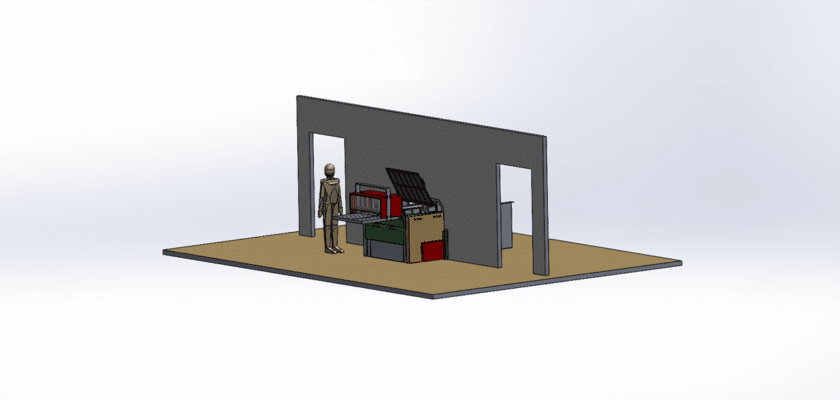

إن رسم حزام ناقل الشوكولاتة provides a comprehensive visual representation of a conveyor system specifically designed for the safe and efficient transport of chocolate and other confectionery products within manufacturing and packaging environments. This drawing highlights the key components, structural features, and operational capabilities essential for handling temperature-sensitive materials.

المكونات الرئيسية الموضحة:

- تصميم الحزام: The drawing prominently features a food-grade conveyor belt, typically made from materials such as FDA-approved rubber or polyurethane. The belt is designed to provide excellent grip and flexibility while preventing melting or deformation of chocolate products during transport.

- هيكل الإطار: Illustrated is the robust frame, often constructed from stainless steel or aluminum, providing stability and durability. The design ensures that the conveyor can withstand the rigors of continuous operation in a chocolate processing environment.

- مجموعة القيادة: The drawing includes details of the drive mechanism, which consists of a motor, pulleys, and gear systems that provide the necessary power to move the conveyor belt. This assembly is crucial for maintaining a consistent speed and reliable operation.

- Temperature Control Features: The conveyor may include temperature regulation components, such as insulated panels or chilled sections, to maintain the ideal temperature for transporting chocolate and prevent melting.

- ميزات السلامة: Important safety elements are emphasized, including emergency stop buttons, safety guards, and access points for maintenance. These features ensure a safe working environment and compliance with food safety regulations.

- نقاط التحميل والتفريغ: Clearly marked intake and discharge points facilitate easy loading of chocolate products onto the conveyor and efficient unloading, optimizing workflow throughout the production process.

- تصميم معياري: The conveyor may feature a modular design, allowing for easy customization and integration into existing production lines, enhancing its adaptability to various operational requirements.

التطبيقات:

- Chocolate Manufacturing: Ideal for transporting chocolate in various forms, including bars, molds, and coated products, throughout the production process.

- عمليات التعبئة والتغليف: Facilitates the movement of finished chocolate products to packaging stations, ensuring efficient sorting, packing, and labeling.

- ضبط الجودة: Can be integrated into quality control processes, allowing for inspections as products move through the conveyor system.

الانطباع العام

إن رسم حزام ناقل الشوكولاتة serves as an essential tool for engineers, designers, and operators involved in the design, implementation, and maintenance of conveyor systems tailored for chocolate handling. By detailing the essential components and their interrelationships, this drawing aids in ensuring efficient and safe transport of chocolate products, ultimately contributing to improved productivity and operational efficiency in confectionery manufacturing environments. Understanding this drawing allows stakeholders to make informed decisions regarding the design and functionality of chocolate conveyor systems to meet specific processing needs.