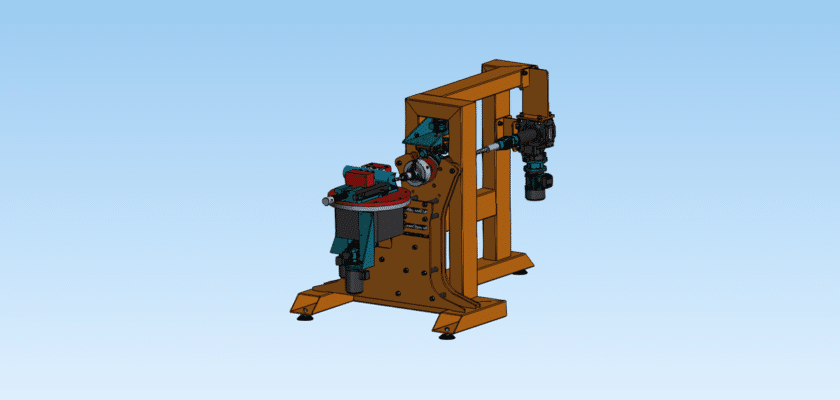

Maximize your production precision by choosing to download our specialized CNC Grooving Machine Tools drawing. Grooving is a critical operation in the manufacturing of pistons, shafts, and bearing housings, where the accuracy of the slot width and depth directly impacts component performance. This technical drawing provides a deep dive into the mechanical architecture of a dedicated CNC grooving station, offering the blueprints for the rigid tool post assemblies and high-speed spindles required to execute clean, chatter-free cuts in hardened materials.

By utilizing this comprehensive CAD resource, mechanical engineers can explore the structural requirements for handling high radial cutting forces. The drawing includes detailed layouts for the servo-driven axes that control the tool path, ensuring sub-micron repeatability for internal, external, and face-grooving operations. Whether you are developing a standalone grooving machine or designing an specialized attachment for a multi-tasking turning center, these schematics provide the necessary data on vibration damping and chip management systems. Having access to these professional-grade blueprints allows your facility to reduce cycle times and achieve a superior surface finish on every workpiece.

الميزات الرئيسية:

- Ultra-Rigid Tool Holder Design: A robust mounting system specifically engineered to resist the high vibrations and deflection forces typical of radial grooving.

- Precision Feed Control: Detailed schematics for high-resolution ball screw assemblies that allow for microscopic increments in plunge depth.

- Integrated Chip Evacuation: An optimized coolant and housing design that prevents chip accumulation within narrow grooves, protecting both the tool and the workpiece.

- Multi-Axis Synchronization: Architectural details for the simultaneous control of X and Z axes to facilitate complex circular or relief grooving profiles.

- Variable Spindle Speed Logic: Structural support for high-torque spindle units that can maintain constant surface speed (CSS) during deep grooving operations.