Optimize your sorting and rejection workflows with our professional Conveyor Line Extraction Mechanism drawing. In high-speed automated logistics, the ability to selectively remove an item from a continuous flow—whether for quality sampling, sorting by destination, or rejecting defective goods—is a critical function. This technical blueprint provides the mechanical logic for a precision extraction unit that can be integrated into belt, roller, or modular chain conveyor systems without disrupting the primary throughput of the line.

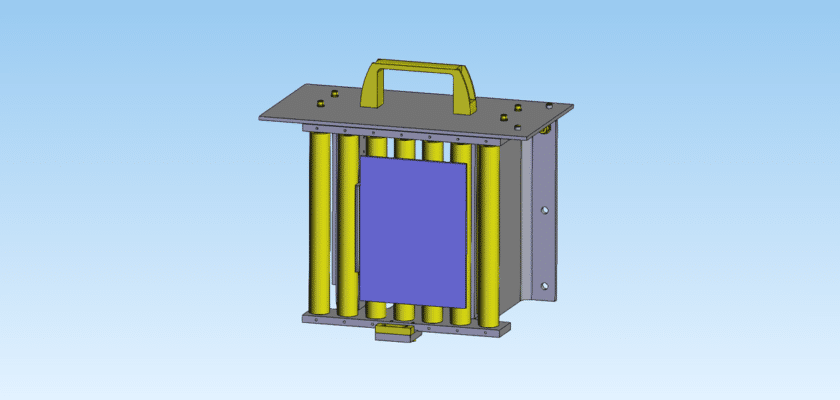

The design focuses on a rapid “Stroke and Retract” cycle, utilizing high-speed pneumatic actuators or servo-driven plungers to strike the target workpiece at the exact moment it passes the extraction zone. By downloading this drawing from MechStream, you gain access to a complete assembly including the pusher head geometry, high-flow solenoid valve mounts, and the shock-absorbing backstops that protect the machinery from repetitive impact forces. This mechanism is engineered for “first-time-right” performance, ensuring that items are moved onto a secondary lane or bin with zero damage to the product or the conveyor belt.

Using this professional-grade resource allows you to bypass the trial-and-error often associated with timing and force calculations. The documentation provides detailed specifications for the linear guides that ensure the pusher arm stays perfectly perpendicular to the flow. Whether you are building a logistics sorting hub or a food-grade packaging line, this extraction mechanism provides the speed, durability, and precision required for 24/7 industrial automation.

الميزات الرئيسية:

- High-Velocity Actuation: Optimized for rapid response times, allowing for the extraction of closely spaced items on high-speed lines.

- Non-Marring Contact Face: Features a detailed design for replaceable polymer or rubber-coated pusher heads to prevent product scuffing.

- Integrated Secondary Lane Interface: Includes the geometry for transition plates that ensure a smooth handoff from the main line to the reject chute.

- Heavy-Duty Linear Guides: Utilizes robust rail systems to handle the significant side-loads generated during high-speed extraction cycles.

- Adjustable Stroke Length: Features a modular design that allows for easy calibration based on varying conveyor widths and product sizes.