Maximize the operational lifespan of your machinery with our professional Design for Improved Wear Resistance drawing. In heavy-duty industrial applications, friction and abrasive wear are the primary causes of premature component failure and costly downtime. This technical CAD resource provides a comprehensive blueprint for implementing advanced wear-mitigation strategies directly into your part geometry. By downloading this file, you gain access to a proven engineering framework that focuses on surface optimization, material selection, and load distribution to ensure your mechanical systems can withstand the harshest environments.

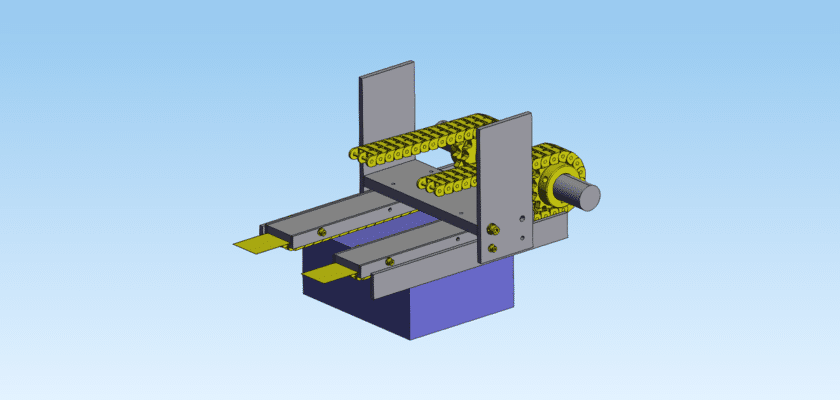

The design featured in this assembly emphasizes the integration of replaceable wear liners and strategic lubrication channels. The drawing includes detailed specifications for surface hardening zones, such as induction hardening or nitriding patterns, and the application of hard-facing overlays. By utilizing this blueprint from ميكستريم, you can transform standard components into high-durability assets. This is an essential resource for engineers designing mining equipment, recycling machinery, or high-speed manufacturing tools where metal-on-metal contact is unavoidable.

Our technical documentation highlights the importance of contact stress management. The assembly is designed with optimized fillet radii and sacrificial elements that protect the main structural chassis. By following this professional engineering framework, your team can significantly reduce the total cost of ownership for industrial hardware by extending maintenance intervals and improving the reliability of moving parts under high-stress conditions.

الميزات الرئيسية:

- Sacrificial Wear Liners: Features detailed designs for easy-to-replace plates that protect primary structural components.

- Optimized Lubrication Geometry: Includes specialized spiral or diamond-pattern grooves to maintain a consistent oil film between moving surfaces.

- Surface Treatment Zones: Clearly defined regions for heat treatment or coatings to enhance local hardness without affecting core toughness.

- Debris Clearance Channels: Engineered paths to move abrasive particles away from critical bearing surfaces, preventing scoring.

- مواصفات المواد المتقدمة: Provides a guide for selecting high-chromium alloys or ceramic inserts based on specific friction profiles.