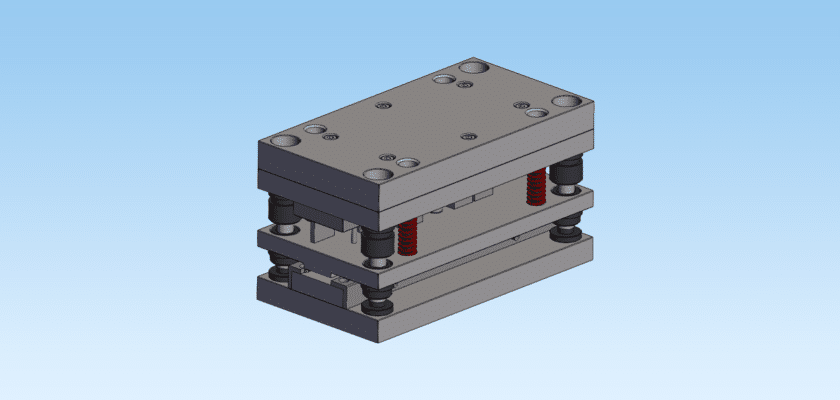

Revolutionize your packaging production with our comprehensive technical documentation for the Easy Open Lids Progressive Die. This complex, multi-station tooling is the pinnacle of high-speed metal stamping, designed to transform flat aluminum or tinplate coils into precision-scored, tabbed, and finished lids in a single continuous process. In the competitive world of food and beverage packaging, achieving consistent score depth and rivet integrity is critical for both safety and consumer convenience. These drawings provide the exact mechanical specifications required to maintain these tight tolerances over millions of high-frequency cycles.

The provided الرسم package offers a deep dive into the sequential stations of the die, including blanking, bubble forming, rivet heading, and the critical scoring stage. By analyzing the precision alignment of the tab-attaching mechanism and the hardened inserts through these blueprints, engineers can optimize the press timing and material feed rates. We offer these high-fidelity CAD resources for free to help packaging engineers and toolmakers reduce prototyping time and ensure a fail-safe opening experience for the end-user.

Our files are formatted for seamless integration into advanced simulation software, allowing your team to verify the thinning of the score line and the structural integrity of the pull-tab before fabrication. Utilizing this professional blueprint ensures that your tooling can handle the intense demands of 24/7 production environments while minimizing scrap and downtime. Download this essential resource today to master the intricate engineering behind modern easy-open ends.

الميزات الرئيسية:

- Multi-Stage Sequential Tooling: Integrated stations for blanking, pre-forming, scoring, and tab-staking within one die set.

- Precision Scoring Control: Features micro-adjustable inserts to maintain consistent residual thickness for easy yet safe opening.

- High-Speed Feed Compatibility: Optimized for integration with automated coil feeders and high-tonnage mechanical presses.

- Tungsten Carbide Inserts: Specifications for high-wear areas to ensure long-term edge retention and minimize maintenance.

- Integrated Safety Sensors: Detailed layouts for misfeed and slug-detection sensors to prevent tool damage during high-speed operation.