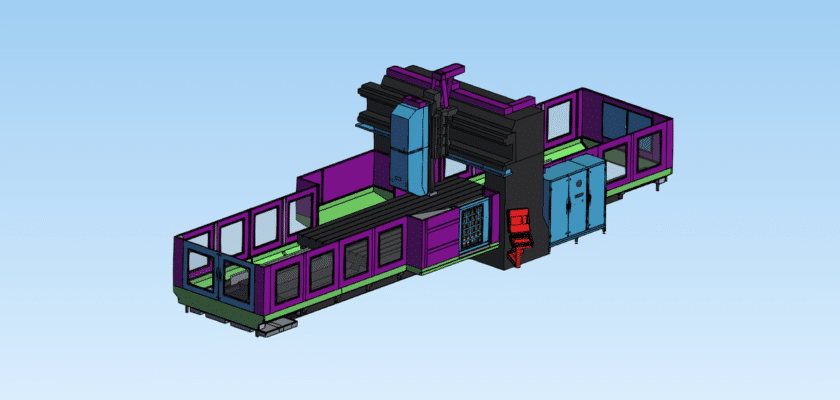

Scale up your manufacturing potential by choosing to download our comprehensive Gantry Milling Machine Tool drawing. When it comes to processing oversized workpieces like engine blocks, mold bases, or aerospace structural components, the gantry (or bridge-type) milling machine is the unrivaled industry standard. This technical drawing provides a deep architectural dive into the massive structural components required to maintain precision over long travel distances. By accessing these schematics, machine designers and factory planners can analyze the load-bearing characteristics of the cross-beam and the high-rigidity columns that define this machine’s superior stability.

By utilizing this professional CAD resource, your team can examine the complex kinematics of the X, Y, and Z axes as they navigate a large work envelope. The drawing highlights the integration of high-torque spindle heads with heavy-duty guideway systems designed to handle immense cutting forces without vibration. Whether you are refurbishing a large-scale manual mill or designing a modern CNC gantry cell from the ground up, these blueprints provide the exact data needed for foundation requirements, motor torque specifications, and tool magazine placement. Download this resource today to master the engineering behind one of the most powerful tools in the metalworking industry.

الميزات الرئيسية:

- High-Stiffness Bridge Design: Detailed schematics of the box-structure cross-beam designed to minimize deflection even when the spindle head is at the center of the span.

- Dual-Drive Synchronization: Structural insights into the synchronized X-axis drive systems that ensure smooth, crabbing-free movement of the gantry along the bed.

- Heavy-Load Table Architecture: Specifications for a reinforced machine bed capable of supporting multi-ton workpieces with sub-millimeter level leveling accuracy.

- Automatic Head-Changing Interface: Detailed layouts for modular spindle attachments, allowing for quick transitions between vertical, horizontal, and universal milling modes.

- Advanced Vibration Dampening: Insights into the internal ribbing and damping material placement within the main castings to ensure superior surface finish quality.