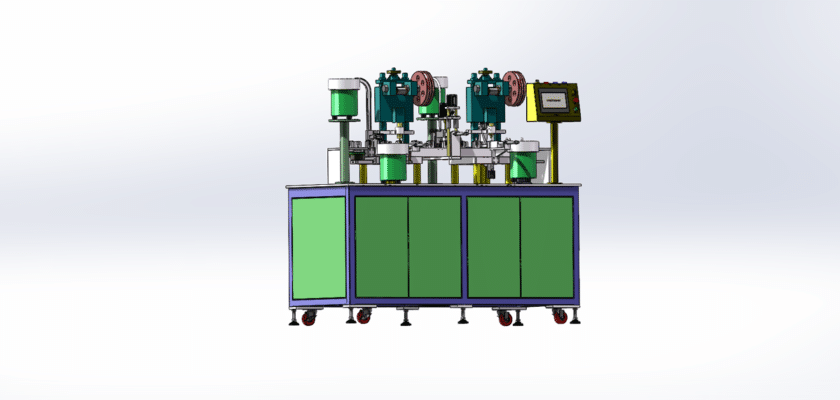

This detailed drawing of the Hardware Stamping and Riveting Automatic Assembly Machine illustrates a sophisticated system designed for the automated stamping and riveting of various hardware components. Ideal for manufacturers in the automotive, aerospace, and industrial sectors, this machine enhances productivity while ensuring high-quality production standards.

الميزات الرئيسية للرسم:

- Integrated Stamping and Riveting Process: The machine combines stamping and riveting operations in a single automated system, streamlining the production workflow and reducing handling time.

- High Precision Stamping Mechanism: Equipped with precision stamping dies, the system ensures accurate shaping and cutting of hardware components, meeting tight tolerances and specifications.

- Automated Riveting Functionality: The riveting station utilizes advanced technologies to securely fasten components, providing strong and reliable joints essential for structural integrity.

- واجهة تحكم سهلة الاستخدام: An intuitive control panel allows operators to easily program and monitor machine operations, facilitating quick adjustments for different component configurations.

- تصميم متعدد المحطات: The machine features multiple workstations that operate in sequence, allowing for simultaneous processing of various hardware parts, thus increasing overall efficiency.

- توافق المكونات المتعددة: Designed to accommodate a wide range of hardware materials and shapes, making it adaptable for diverse assembly applications across multiple industries.

- أنظمة مراقبة الجودة المتكاملة: Built-in inspection mechanisms continuously monitor the stamping and riveting processes, ensuring that each finished product meets quality standards and minimizing defects.

- بناء قوي ودائم:تم تصنيع الماكينة من مواد عالية الجودة، وتم تصميمها لتكون طويلة الأمد وموثوقة، مما يضمن الأداء الأمثل في بيئات الإنتاج ذات الحجم الكبير.

This drawing serves as a vital reference for engineers and manufacturers seeking to implement effective and efficient stamping and riveting solutions in their production lines.