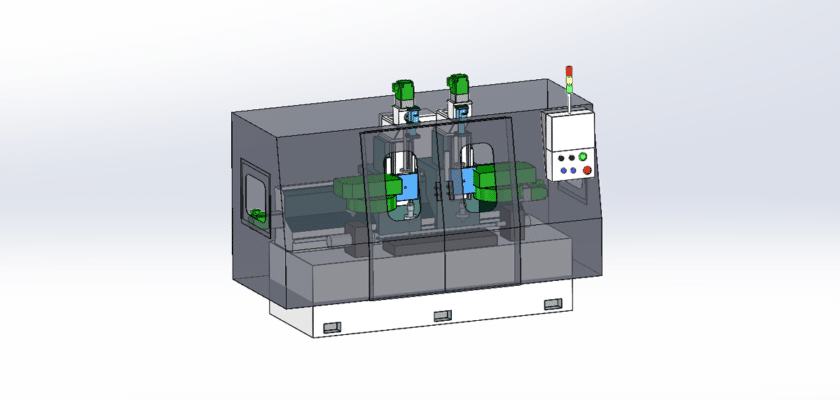

يوضح هذا الرسم التفصيلي لآلة الحفر بالذوبان الساخن نظامًا متطورًا مصممًا خصيصًا لدمج مواد اللصق بالذوبان الساخن في عمليات الحفر. صُممت هذه الآلة لتحسين الكفاءة وضمان التصاق موثوق، وهي مثالية للتطبيقات في صناعات السيارات والتعبئة والتغليف والنجارة.

الميزات الرئيسية للرسم:

- تطبيق الذوبان الساخن المتكامل:تجمع الماكينة بين قدرات الحفر وتوزيع المادة اللاصقة الساخنة بدقة، مما يعزز سير العمل التصنيعي الشامل.

- التحكم عالي الدقة:مجهز بأجهزة استشعار وأنظمة تحكم متقدمة، فهو يضمن تطبيقًا دقيقًا للمادة اللاصقة أثناء الحفر، مما يحسن الالتصاق ويقلل من النفايات.

- واجهة سهلة الاستخدام:تتيح لوحة التحكم البديهية إجراء تعديلات وبرمجة سهلة، مما يسهل التغييرات السريعة للمواد المختلفة ومتطلبات الإنتاج.

- توافق المواد المتعددة:مناسب لمجموعة من المواد الأساسية، بما في ذلك البلاستيك والخشب والمركبات، مما يجعله قابلاً للتكيف مع احتياجات التصنيع المختلفة.

- بناء قوي ودائم:تم تصنيع الماكينة باستخدام مواد عالية الجودة، وهي مصممة لتكون موثوقة وطويلة العمر، مما يضمن أداءً ثابتًا في البيئات الصناعية الصعبة.

يُعد هذا الرسم بمثابة مورد حيوي للمهندسين والمصنعين الذين يسعون إلى تنفيذ حلول فعالة وكفؤة لحفر الذوبان الساخن في عمليات الإنتاج الخاصة بهم.