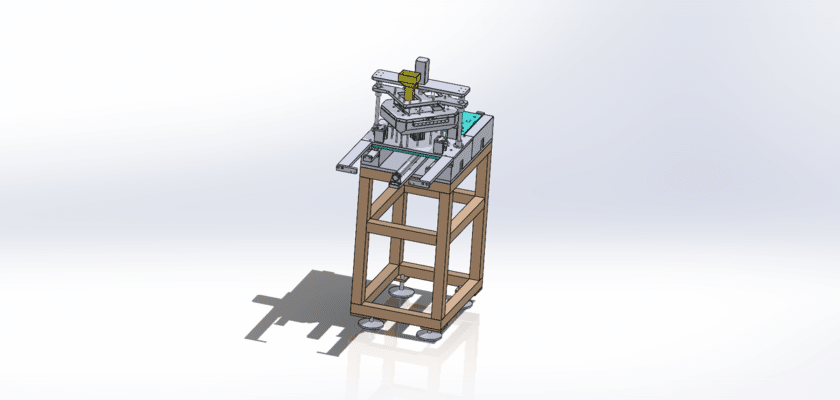

آلة غرس الصواميل بالصهر الساخن هي أداة تجميع متخصصة مصممة لدمج حشوات الصواميل بكفاءة في مواد مختلفة باستخدام تقنية الصهر الساخن. توفر هذه الآلة طريقة موثوقة لغرس الصواميل بأمان، مما يضمن قوة ومتانة عالية في تطبيقات متعددة الصناعات، بما في ذلك صناعة السيارات والإلكترونيات والأثاث.

الميزات الرئيسية

- تقنية الذوبان الساخن:يستخدم لاصقًا ساخنًا لتثبيت الصواميل في الركائز، مما يوفر رابطًا قويًا يعزز سلامة المكونات المجمعة.

- التشغيل الآلي:تقوم الآلة بأتمتة عملية زراعة الجوز بالكامل، من تطبيق المادة اللاصقة إلى وضع الجوز، مما يقلل من العمل اليدوي ويزيد من الكفاءة.

- التحكم الدقيق في درجة الحرارة:مجهزة بأنظمة تسخين متقدمة تضمن درجة حرارة لاصقة مثالية للترابط الفعال، ومنع مشاكل مثل ارتفاع درجة الحرارة أو عدم كفاية الالتصاق.

- واجهة سهلة الاستخدام:يتميز بلوحة تحكم بديهية تسمح بالبرمجة السهلة ومراقبة عملية الزرع، مما يجعلها في متناول المشغلين من جميع مستويات المهارة.

عناصر

- وحدة التدفئة:عنصر أساسي يذيب المادة اللاصقة إلى درجة الحرارة المطلوبة، مما يضمن الترابط الفعال مع صمولة الإدخال.

- آلية تغذية الجوز:نظام آلي يقوم بتزويد موقع الزرع بالصواميل، مما يضمن سير العمل المستمر والفعال.

- نظام تطبيق اللاصق:يقوم بتوصيل المادة اللاصقة الساخنة بدقة إلى المنطقة المحددة، مما يسهل وضع الصواميل بدقة.

- نظام التحكم:وحدة تعتمد على PLC لإدارة عمليات الماكينة، وتوفير ردود الفعل في الوقت الحقيقي والسماح بإجراء تعديلات سريعة.

التطبيقات

- صناعة السيارات:مثالي لتضمين الصواميل في مكونات السيارة، مما يعزز قوة التجميع والسلامة الهيكلية.

- تصنيع الإلكترونيات:مناسب لتأمين الصواميل في الأجهزة الإلكترونية، وضمان التوصيلات الموثوقة والمتانة.

- إنتاج الأثاث:فعال لتضمين الصواميل في مكونات الأثاث المختلفة، مما يساهم في تحسين الاستقرار وطول العمر.

خاتمة

تُعد آلة غرس الصواميل المصهورة بالحرارة أداةً أساسيةً للمصنعين الذين يسعون إلى تحسين كفاءة وجودة عمليات تكامل الصواميل. فميزاتها الآلية، وتحكمها الدقيق في درجة الحرارة، وتصميمها سهل الاستخدام، تجعلها أداةً قيّمةً في مختلف التطبيقات الصناعية. وتُجسّد هذه الآلة التطورات في تكنولوجيا التجميع، مما يُسهم في تبسيط العمليات وتحسين موثوقية المنتجات في مختلف القطاعات.