Eliminate production bottlenecks and improve operator safety with our professional Loading and Unloading Workpieces system drawing. The “First and Last Mile” of any manufacturing process—getting the raw part into the machine and the finished product out—is often the most labor-intensive. This technical CAD resource provides a comprehensive blueprint for an automated machine-tending station. By downloading this file, you gain access to a proven design that synchronizes workpiece arrival, orientation, and extraction, allowing your CNC centers or assembly presses to run at 100% duty cycle.

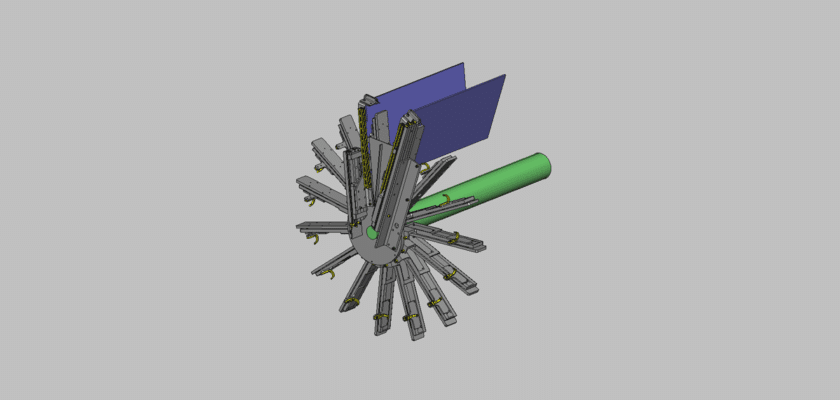

The design featured in this package focuses on a dual-gripper “exchange” system. This mechanism allows the robot or gantry to carry a raw part and a finished part simultaneously, reducing the exchange time to mere seconds. The drawing includes detailed layouts for gravity-fed chutes, vibrating bowl feeders, and the precise mechanical stops required to seat the workpiece into a fixture. By utilizing this blueprint from ميكستريم, you can transform a manual operation into a “lights-out” manufacturing cell, significantly lowering your cost per part.

Our technical documentation prioritizes workpiece protection and positional accuracy. The assembly is designed with non-marring contact points and sensors that verify “part-seated” status before the machine cycle begins. Whether you are designing a shuttle system for a vertical machining center (VMC) or a pick-and-place unit for an injection molding machine, this drawing provides the exact geometric relations, pneumatic timing logic, and structural mounting details required for high-speed, reliable material handling.

الميزات الرئيسية:

- Dual-Action Exchange Grippers: Designed to hold both the raw and finished workpiece to minimize machine idle time during the swap.

- Orientation Verification: Includes mechanical or sensor-based “gates” to ensure the workpiece enters the fixture in the correct direction.

- Integrated Blow-Off Stations: Features schematics for air nozzles that clear chips and coolant from the part and fixture during the unloading phase.

- Modular Feed Interfaces: Compatible with various input methods, including conveyors, pallets, or stackable trays.

- Emergency Egress Paths: Designed with clearance for manual intervention or maintenance without needing to disassemble the entire loading gantry.